Energy-autonomous sensors monitor the condition of railway freight cars

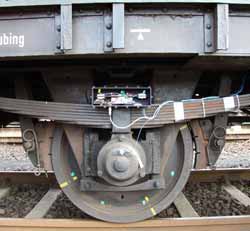

Energy-autonomous sensor nodes undergoing field test. Photo: Fraunhofer LBF<br>

Nevertheless, its market share has been going down continuously compared to road transport. Progress might be made with regard to overcoming this shortfall, if it were possible to monitor freight cars in operation.

This would enable an early detection of imminent damage and at the same time provide for condition-based maintenance. Freight traffic would become economically more efficient and significantly safer.

Researchers at the Fraunhofer Institute for Structural Durability and System Reliability have now developed a new solution for continuous condition monitoring of railway freight cars, based on intelligent, energy-autonomous sensors, enabling damage to be detected at an early stage and accidents to be avoided.The system can be flexibly configured, and even retrofitted into existing equipment. Fraunhofer LBF will be showcasing the new solution at the Innotrans exhibition at its Booth No. 225 in Hall 4.1.

Given the harsh operating conditions with severe loads re-sulting from vibrations, temperature variations, dirt and humidity, railway equipment needs to be simple and robust. Freight cars therefore generally do not have any onboard sensors or power supply. Hence the Darmstadt researchers created a method for the development of intelligent, energy-autonomous sensor nodes for structural monitoring.

The purpose of such nodes is to analyze and transmit data, using a limited amount of energy. In the course of the development, the research team employed advanced simulation and real-time simulation tools along with Hardware-in-the-Loop methods to efficiently advance development from the first draft to the first prototype through systematic testing.

The development team at Fraunhofer LBF designed an energy harvesting system capable of converting energy present in the ambient environment in order to supply the sensor node, the energy source “tapped into” being the mechanical vibrations of the railway wagons. As ambient energy is not continuously available, the research team developed an energy management system adapted to the requirements of the application on hand, which enables the reliable acquisition, processing and wireless transmission of measurement data.

A special challenge presented itself in connection with the need for reliable transmission of the data to the driver, which resulted from the fact that there are numerous sources of interference along the transmission path. The researchers implemented the condition monitoring system using a hot box detector for monitoring of wheel bearings.

Availability of energy at the place of application

The key element of the energy-autonomous sensor system is the condition monitoring software. Several algorithms are available, which provide information regarding the proper functioning of a system or calculate its residual life.

Considering the limited amount of ambient energy avail-able onboard the freight car, an integrated approach had to be taken in the design of the energy-autonomous sensor system (EASS). At the outset of the methodical development process, the developers conducted an extensive measurement to determine the system dynamics and the service loads present on the freight car. Based on the measurement data obtained, they were able to determine an application site, at which sufficient energy to operate an EASS can be harvested. The Fraunhofer LBF researchers then designed a mechanical resonator optimized for this site, with applied piezoelectric transducers to convert mechanical vibrations present in the ambient environment with high efficiency into electrical energy.

Hardware and software for energy management and for data processing and transmission are complex systems, whose interaction was initially analyzed and optimized by the Darmstadt research team in the laboratory by means of Hardware-in-the-Loop simulations. This enabled the mechatronic systems to be assessed under realistic conditions, realistic ambient condition to be reproduced and prototype electronic devices to be evaluated. Hence, at the beginning of the development process, many of the EASS components were represented by real-time computer models and individual hardware components numerically optimized. Following successful adaptation, the system components were gradually replaced by prototypes, until a well-coordinated energy-autonomous sensor system was achieved. Upon successful implementation in the laboratory, the system was evaluated in a field test.

Improving products through “Usage Monitoring”

The new sensor nodes may help the railway industry to improve its competitiveness against other forms of transport. Condition-based monitoring of safety relevant components, made possible by the sensor node, will reduce cost compared to conventional interval-based maintenance. At the same time, the new solution maintains the capability to arbitrarily assemble train sets. Continuous data acquisition in the form of “Usage Monitoring” can be used for product improvement, as the designer is provided with more accurate information about usage profiles. In addition, enhanced condition monitoring improves operational safety and contributes towards avoiding serious accidents.

Media Contact

More Information:

http://www.lbf.fraunhofer.deAll latest news from the category: Trade Fair News

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…