Dual gloss: producing innovative surface designs by laser remelting

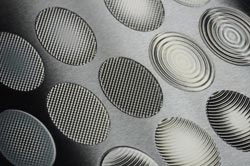

Fig. 1: Surface with variable structures produced by laser remelting. Fraunhofer Institute for Laser Technology ILT, Aachen.<br>

For the first time, this method makes it possible to structure materials without resorting to ablation and at the same time to polish them to a brilliant gloss finish. This gives tool manufacturers greater scope to adapt their production processes to incorporate novel structures and design elements while also saving them time and money. Another new technique can additionally be used to provide tools and products with a dual-gloss effect.

From steering wheels to toothbrush handles, we have become accustomed to the look and feel of structured surfaces on components we encounter in virtually all areas of our lives. Injection molding tools made from metal are often used to give these components their structure, and one method that is commonly used to produce the desired structure on the tools themselves is photochemical etching, where specific regions of the tool insert are structured by etching away the unwanted regions. However, this is a costly and time-consuming process which requires the use and disposal of large quantities of environmentally hazardous acids.

A more environmentally-friendly alternative is the technique of laser structuring by ablation, which has been used successfully for more than ten years. This method can achieve ablation rates of 1-10 mm3/min in processes designed to create structures > 10 µm, but in many cases the workpiece subsequently requires further treatment to remove the melt residue which accumulates during ablation. In addition, the laser requires some ten passes to achieve a structure depth of 200 µm, which means that the laser-based structuring of large surfaces through ablation is generally not a cost-effective option for tool manufacturers.

Remelting instead of ablation

Fraunhofer ILT has now developed a method of structuring tools using laser remelting. The laser beam travels over the workpiece and the resulting heat input melts the metal surface. At the same time, the laser power is modulated in order to continuously change the size of the melt pool at defined points. »This modulation causes the material to be redistributed, creating mountains and valleys: half of the resulting structure lies above its initial level, while the other half lies below it,« says André Temmler, project manager at Fraunhofer ILT. Thanks to surface tension, when the uppermost layer of the molten material solidifies, it exhibits uniformly low roughness, and the surface is left with a brilliant polished finish. Unlike laser structuring by ablation, the novelty of laser structuring by remelting is its ability to directly produce finished surfaces which do not require any post-processing. For a structure depth of approximately 200 µm, this method can achieve processing rates of up to 75 mm2/min, enabling a volume redistribution rate of 15 mm³/min in a single pass. A further advantage of this new method is that it consumes less energy and fewer resources than conventional laser-based structuring by ablation. Less energy is required for melting than for sublimation, the process requires significantly fewer passes, and there is no loss of material. Depending on the material and batch size, these benefits can yield considerable time and cost savings for tool manufacturers. For flat surfaces and single-curved component geometries, the laser technique of structuring by remelting is already available for industrial use. Temmler and his team are now working on applying the technique to freeform surfaces.

Dual-gloss effect by selective laser polishing

In cases where an additional dual-gloss effect is required for end products such as decorative elements or an entire product surface, the first step is to apply a matt finish to the whole surface of the tool, which is generally achieved through blasting with glass beads or sand. Selected regions are then remelted using a laser beam. These regions solidify from the melt with a polished finish – in other words, the selective laser polishing creates a contrast between the matt, untreated areas and the brilliant, laser-polished areas. Depending on the intensity of the dual gloss, this can even produce a 3D effect in which the polished points appear to protrude from the surface. One example of how selective laser polishing can be used is to provide structured tools designed to apply a leather grain structure to plastic components with a dual-gloss effect which is then transferred to the end product during the molding process. For the first time, this selective polishing technique can now be applied on an industrial scale for both flat and freeform surfaces.

Visitors to the joint Fraunhofer Booth C66 in Hall 11 at EuroMold 2011 will have the opportunity to see components produced with workpieces which were laser structured by remelting. Our experts will also be presenting a selection of sample objects molded in plastic by selectively laser-polished tools.

Your contacts at the Fraunhofer ILT

Our experts are on hand to answer your questions:

André Temmler

Polishing

Phone +49 241 8906-299

andre.temmler@ilt.fraunhofer.de

Dr. Konrad Wissenbach

Additive Manufacturing and Functional Layers

Phone +49 241 8906-147

konrad.wissenbach@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstrasse 15

52074 Aachen

Phone +49 241 8906-0

Fax +49 241 8906-121

Media Contact

More Information:

http://www.ilt.fraunhofer.deAll latest news from the category: Trade Fair News

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…