Come Together: Teamwork Achieves Optimum Composite Design

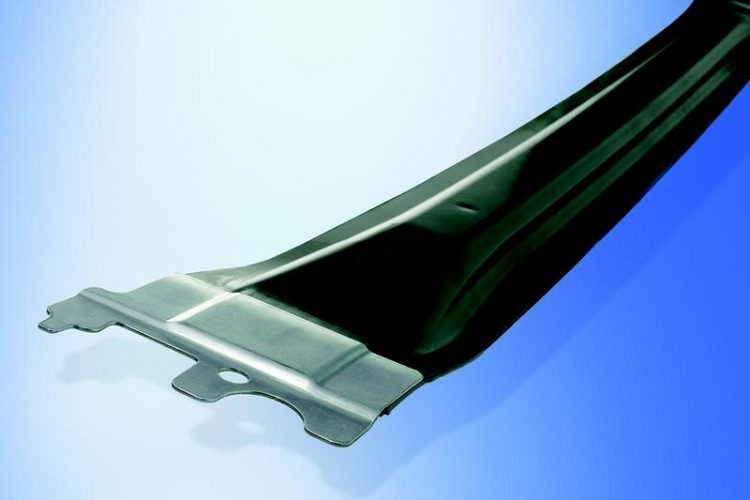

Multi-material roof bow: At the JEC World Composite Show in Paris this March, Fraunhofer LBF and ILT will use this exhibition piece to demonstrate how costs and process time can be reduced. © Fraunhofer ILT, Aachen, Germany

Within the HyBriLight project sponsored by Germany’s Federal Ministry of Education and Research, a hybrid component has been developed that demonstrates the successful implementation of new innovative laser processes in lightweight production.

The hybrid component is what is known as a roof bow, based on an original component of a BMW 7 Series vehicle. It consists of a fiber-reinforced plastic brace bonded to two metal connecting plates. These attach the part to the chassis. As an alternative to the glue and rivets used up to now, the Fraunhofer ILT has developed a new laser-based bonding process that joins plastic and metal via positive locking and adhesion.

Ultrafast pulse laser gives the metal surface its special structure

An ultrafast pulse laser first generates sponge-like micro and nano structures on the joining partners’ metal surface. Next, the fiber-reinforced plastic brace is compression molded and joined to the metal plates in the same process step. This requires the connecting plates to be placed in a special variothermal mold.

Then, during the compression molding process, polymer melt fills the metal structures. Once solidified, the plastic and the metal form a strong and durable bond through clawing. Local tape reinforcement increases the component’s rigidity. The component is then trimmed by fiber laser in a multi-pass process.

Fraunhofer LBF has optimized the design of this special hybrid connection. “We used material samples to analyze the static and cyclical loads,” says Dominik Spancken, Experimental Durability Plastics business team leader at Fraunhofer LBF. Those findings are used to estimate the component’s service life, and are validated by experimental tests.”

High tensile shear strength thanks to optimized design

Through the teamwork of these two Fraunhofer Institutes and their industrial partners, it has been possible to create with a validated process a hybrid component with a shear strength of nearly 50 MPa. To be able to produce this part more cost efficently, a thermoplastic glass fiber reinforced PA6 matrix is used instead of the carbonfiber reinforced Duroplast brace. In order to maintain the original part’s rigidity and stability, parts of the roof bow were locally reinforced using unidirectional carbon fiber tape. The cycle time for producing one component is around 75 seconds.

Process time reduced 70 percent

“The result is something to be proud of,” says project coordinator Kira van der Straeten, a scientist in the Plastics Processing Group at Fraunhofer ILT. “This innovation achieves a 70 percent reduction in process times compared to conventional processes, a 45percent reduction in raw material costs and the integration of multiple process steps into one highly automated process.”

Project HyBriLight

The BMBF project HyBriLight is creating photonic tools for lightweight engineering. This is specifically about a “process chain tailored to the material for cost-efficient hybrid lightweight construction using highly productive laser systems” that will herald the transition from manufacture to series production. Project participants: Fraunhofer Institute for Laser Technology ILT, Aachen (project coordination); Fraunhofer Institute for Structural Durability and System Reliability LBF, Darmstadt; Weber Fibertech GmbH, Markdorf; Werkzeugbau Siegfried Hofmann GmbH, Lichtenfels; Scanlab GmbH, Puchheim; Bayerische Motoren Werke Aktiengesellschaft, Munich; Airbus Group Innovations, Munich; Dilas GmbH, Mainz; Held Systems GmbH, Heusenstramm.

Contact

Kira van der Straeten M. Sc.

Microjoining Group

Telephone +49 241 8906-158

Kira.van.der.straeten@ilt.fraunhofer.de

http://www.ilt.fraunhofer.de/en

https://www.ilt.fraunhofer.de/en/fairs-and-events/fairs/jec_world_2018.html

Media Contact

All latest news from the category: Trade Fair News

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…