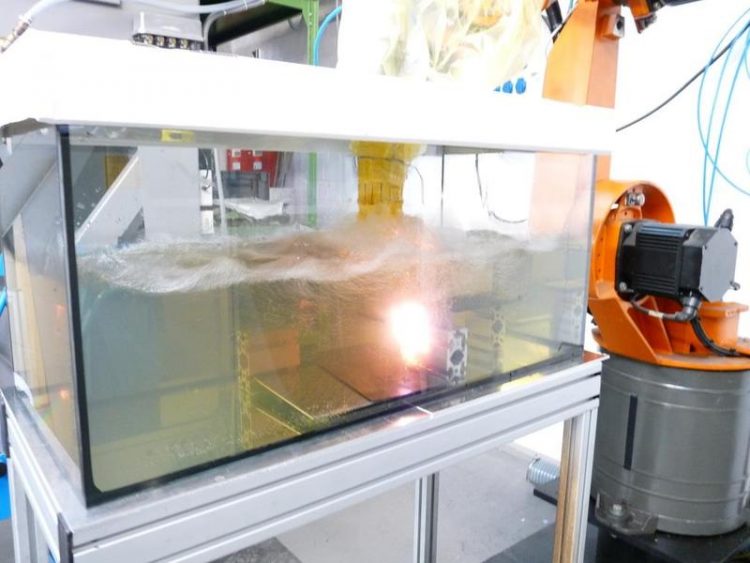

Underwater laser cutting

Underwater laser cutting is a fast and thus economical alternative to conventional processes. Photo: LZH

For maintenance and repair of metal constructions, a number of processes are available, but these are time consuming and difficult on the divers.

For this reason, engineers at the Laser Zentrum Hannover e.V. (LZH) and the Leibniz Universität Hannover (LUH) are developing a process for automated, underwater laser cutting.

At the moment, mainly light arc oxygen cutting is being used for underwater cutting. The electrodes are hand-guided. Depending on the material thickness, divers need a workday to cut 20 meters in material. For a diving period of five hours this means a cutting speed of only 7 centimeter per minute.

Cutting seven times faster

With a laser-based automated process, the cutting speed should be increased by a factor of seven. “During pilot tests, we have already achieved a cutting speed of 0.5 meters per minute for 10 millimeter thick steel” says Dr.-Ing. Jörg Hermsdorf, head of the Machines and Controls Group at the LZH.

“With this process, underwater metal working could be considerably faster and thus less expensive. Our goal is to make the work of the divers safer and more efficient.”

Efficient dismantling of sheet piling

The process is being developed for dismantling sheet pilings in two to six meters deep water. For this, it is crucial that the pilings including the interlocks are reliably cut, as post processing is time-consuming and expensive. Since metal part corrode under water and are subject to overgrowth, the process is supposed to function reliably, even for varying material thicknesses and pollution levels.

The finished process could also be used for the maintenance and repair of offshore structures and other hydraulic structures. Also, dismantling of nuclear power plants is a further field of application.

The project “Laser cutting under water for higher productivity – LuWaPro” is supported by the German Federation of Industrial Research Associations “Otto von Guericke” e.V. (AiF).

http://www.lzh.de/de/publikationen/pressemitteilungen/2014/laserschneiden-unter-… – website with press realease and additional video

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…