Research project AutoAdd: Paving the way for additive manufacturing for the automotive industry

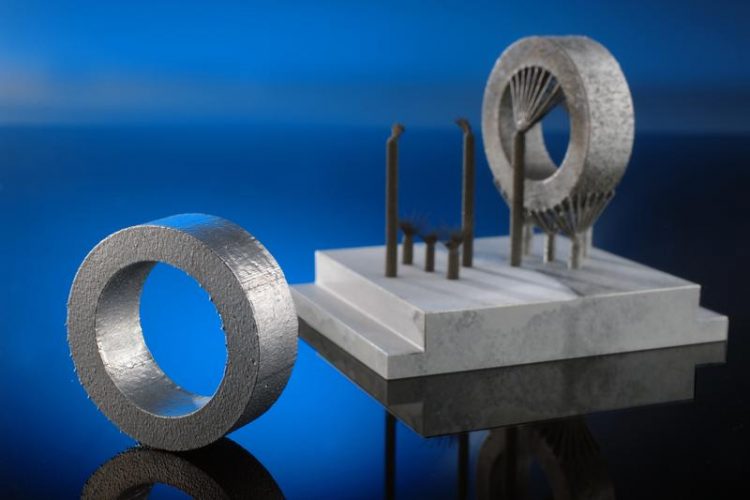

Test piece, with supports removed with a wet-chemical process. © Fraunhofer ILT, Aachen, Germany

The German Federal Ministry of Education and Research (BMBF) wants to literally bring light into production under the term “Photonic Process Chains”.

Research projects are to integrate photon-based manufacturing processes such as metal 3D printing into product planning processes. The project aims to develop flexible, hybrid manufacturing conceptual designs, which the industry can use to produce individualized and complex products more efficiently than before.

Hybrid process chain to reduce unit costs

Of the 14 joint projects within the funding initiative, the AutoAdd project aimed to make it easier for the automotive industry to use additive manufacturing within three years.

The project partners focused on integrating the LPBF process chain in the automotive mass production environment to create a hybrid process chain and, thus, to reduce unit costs.

The BMW Group and Daimler defined the requirements for the additive process chain, which the high-tech company TRUMPF and research institute Fraunhofer ILT used to develop various LPBF plant and finishing conceptual designs.

The result was potentially production-ready optical designs as well as a modular system architecture, which, for example, enables the use of multiple beam sources and a so-called interchangeable cylinder principle.

In addition, the project team developed promising automatable post-processing concepts, including removal of support structures, and analyzed novel scalable materials produced by GKN.

Finally, the Karlsruhe Institute of Technology (KIT) evaluated the new factory designs: Using a simulation model, the engineers of the wbk Institute for Production Science visualized an exemplary, conventional process chain, in which they were able to design various possible LPBF plant concepts. With methods such as cost or benchmark analyzes, they were able to compare the new approaches from a technical and economic point of view with previous ones.

Additive mass manufacturing made possible

The results of the three-year joint project are quite impressive: Since modular cylinders and the use of wet-chemical immersion baths can now be used to remove, batchwise, components in the post-processing step, the entire process chain can be automated and non-productive time saved.

This can increase the overall profitability. The AutoAdd project team has also developed common metrics for evaluating LPBF manufacturing equipment and identified them for the most popular equipment manufacturers as part of a large-scale benchmarking exercise.

By using standardized benchmark jobs with different test specimens, industrial users can now calculate transferable key figures with which they will be able to find the most economical system for their purposes.

In addition, a fundamental step was taken: One of the most important points needed to make additive manufacturing technology ready for series production – the reproducibility of the mechanical properties – was demonstrated and evaluated in several state-of-the-art facilities. Integrating an economic additive process chain in automotive mass production can now be considered possible after the end of the project.

From an academic point of view, the research project also brought about positive effects: Content emerged from AutoAdd for four dissertations, and the knowledge thus gained can also be used for lectures. Moreover, in 2019 there will be another project, partly based on the present results, dealing with the line-integration of additive manufacturing processes to implement the designed additive process chain.

Research project »Integration of Additive Manufacturing Processes in Automobile Production -AutoAdd«

Project partners:

– Bayerische Motoren Werke AG, Munich, Germany

– Daimler AG, Ulm, Germany

– Fraunhofer Institute for Laser Technology ILT, Aachen, Germany

– GKN Sinter Metals Engineering GmbH, Radevormwald, Germany

– Karlsruhe Institute of Technology (KIT), Karlsruhe, Germany

– netfabb GmbH, Lupburg, Germany

– TRUMPF Laser- und Systemtechnik GmbH, Ditzingen, Germany

Project period: June 1, 2015 to May 31, 2018

Project volume: €3.37 million, (about a 57 percent share of funding from the Federal Ministry of Education and Research BMBF).

Tobias Schmithüsen

Group Laser Powder Bed Fusion

Telephone +49 241 8906-568

tobias.schmithuesen@ilt.fraunhofer.de

https://www.ilt.fraunhofer.de/en

https://www.photonikforschung.de/projekte/photonische-prozessketten/projekt/auto…

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…