LIMBO: Innovative joining technology for temperature-sensitive components

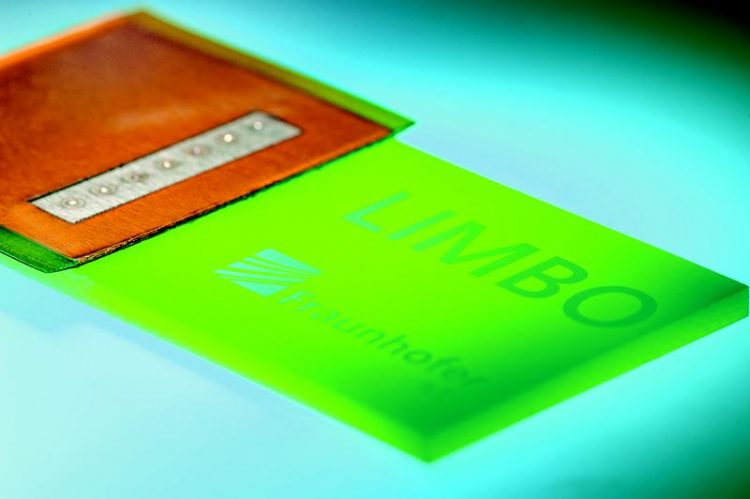

A 200 µm thick copper ribbon on a PCB joined via the LIMBO process. © Fraunhofer ILT, Aachen, Germany.

The five letters stand for a development from Aachen that is meant to inspire specialists from the electronics manufacturing sector: they are talking about another kind of “LIMBO,” the acronym for “Laser Impulse Metal Bonding.”

“This laser process expands the process limits of conventional welding and soldering processes considerably,” explains Dipl.-Ing. Simon Britten, head of the LIMBO project.

“It opens up completely new fields of applications for the joining of temperature-sensitive components.” Within three years, the researchers have developed a thermal joining process that overcomes the limitations of conventional methods and deposits only a minimum of energy in the components.

This enables the unprecedented joining of components such as thick ribbon interconnectors in power electronics with sensitive, fast-switching chips (e.g. for wind turbines or electric vehicles). In contrast to soldering, the contacts have a high temperature stability and show, in comparison to conventional welding or bonding, a minimal effect on the component.

Joined cool

“Thanks to LIMBO, we can now also thermally join thick ribbons that have a thickness of 200 µm or more with thin metallization layers,” says the expert on micro joining. “The secret is in breaking up the classical welding process into the separate phases of heating and joining.”

In contrast to typical electrical connecting processes, here a relatively large gap is used, in which a thermally isolated weld pool forms. Britten: “We control the process – which lasts a total of less than 20 milliseconds – so that the connection is essentially made solely by the energy in the melt, and not by the laser beam. This leads to a minimal energy input.”

In a process where embossment or isolation material is used to create gaps of more than 50 µm, the LIMBO process can be applied when the metallization layer has a thickness in a two-digit micrometer range. At productronica, Fraunhofer ILT will demonstrate the process using a fiber laser (wavelength: 1070 nm).

“All laser sources that can be modulated in the range of milliseconds to microseconds can be used,” explains the scientist. “What is needed for the short exposure time is a laser power of about two kilowatts, but with the fiber laser around 500 watts are also sufficient.”

Experts will be showing possible applications of LIMBO at the productronica

Now that Fraunhofer ILT has laid the basic groundwork, the project manager and his team are certain how LIMBO works and that it is reliable. “This process can be considered – thanks to its low penetration depth of less than 20 microns – for many applications with heat-sensitive components,” says Britten.

The range of possible applications for LIMBO is very broad: it extends from inserts in control technology for alternative energy (keyword: power electronics for inverters of wind turbines) to electro mobility.

“We are helping prospective customers adapt the process to their applications by means of functional models.” Interested parties can find out more about LIMBO and its potential applications at the productronica in Munich from November 10 to 13 at the Fraunhofer Joint Booth 2017 in Hall B3.

Contact

Dipl.-Ing. Simon Britten

Micro Joining Group

Telephone +49 241 8906-322

simon.britten@ilt.fraunhofer.de

Dr. Alexander Olowinsky

Head of the Micro Joining Group

Telephone +49 241 8906-491

alexander.olowinsky@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52047Aachen, Germany

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…