High Quality and Process Stability for Welding Copper

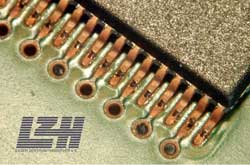

Welded contacts on an IC (TSOP 0.5mm pitch) on a printed circuit board (Ilfa) using a laer pre-pulse and IR laser main pulse.<br>

Using a short laser pre-pulse, the contacts are treated to provide 100 per cent good welds for the subsequent infrared welding.

A newly developed “laser pre-pulse module” can be used to initiate the copper welding process and provide a 100% welding guarantee. The laser is small and inexpensive, the result of process developments at the Laser Zentrum Hannover e.V. (LZH). The pre-pulse is decisive for automating micro-processing, or for connecting surface mounted devices to printed circuit boards.

Copper alloys are often found in electronics, sensors and precision engineering applications. Here, high demands are placed on the heat and mechanical stress resistance of spot welds, and laser micro-welding has very good weld qualities. However, non-ferrous metals are difficult to weld, due to high reflectivity, and a sudden jump in energy absorption when the melting temperature is reached. It is difficult to repeat good welding results, and with low process stability, up to now lasers have only been used following complex surface treatment, or for manual applications.

Researchers at the Department of Production and System Technology at the LZH have developed a new process, which uses a laser pre-pulse with a peak output of no more than 1 MW and a pulse length of only a few nanoseconds to initiate the welding process. This short-pulsed, solid-state, frequency converted laser has a high degree of absorption, and provides stable conditions for the subssequent high-output welding using a conventional IR laser. The welding energy can be easily controlled after pre-pulsing.

Experiments using the pre-pulse prototype of the company neoLASE were carried out on an 80 µm thick, 2mm wide copper band. After 200 repetitions, the welding results were constant, implying that the welds were 100% good. “This result is already a great success,” says engineer Anas Moalem, who is responsible for the development of the process. Apart from improved precision and quality, the process window for the laser parameters could be expanded considerably.

Depending on the weld spot diameter, the laser output power could be reduced by up to 40%, meaning that using the compact pre-pulse module (13 x 9 x 4 cm) could result in energy savings in the kilowatt range for the IR welding lasers.

Developments took place within the framework of the SME-innovation project “Supreme”, which was financed by the BMBF (German Federal Ministry of Education and Research) under supervision of the PTKA-Project Management Agency Karlsruhe. Support was also given by the companies Arteos GmbH, Ilfa GmbH, neoLASE GmbH and Sill Optics GmbH & Co. KG.

Contact:

Laser Zentrum Hannover e.V.

Michael Botts

Hollerithallee 8

D-30419 Hannover

Germany

Tel.: +49 511 2788-151

Fax: +49 511 2788-100

E-Mail: m.botts@lzh.de

The Laser Zentrum Hannover e.V. (LZH) carries out research and development in the field of laser technology and is supported by the Ministry of Economic Affairs, Labour and Transport of the State of Lower Saxony (Niedersächsisches Ministerium für Wirtschaft, Arbeit und Verkehr).

Media Contact

More Information:

http://www.lzh.deAll latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…