Efficient reactor dismantling by laser beam cutting?

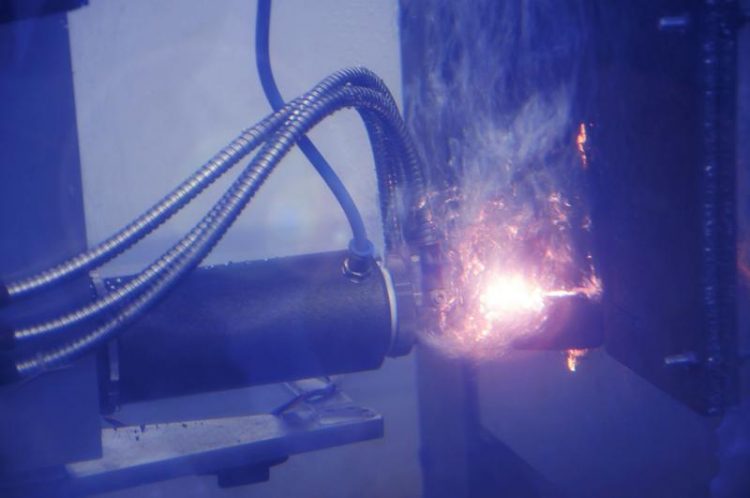

Underwater laser cutting offers enormous potential for the dismantling of reactor vessels. Photo: LZH

This new system is supposed to enable the direct dismantling of nuclear facilities (reactor pressure vessels). Laser beam cutting offers significant advantages compared to conventional cutting methods, such as water jet cutting or sawing techniques.

Above all, the binding of the kerf material on the exit side is a major advantage of the laser process. The expense for the final cleaning of the water basin floor is significantly reduced, as the amount of secondary or technology waste is significantly lower compared to water jet or sawing techniques.

The disposal of this waste is time-consuming and costly. In addition, sawing techniques are prone to jamming of the tool. This cannot occur with laser beam cutting. Thus, the process times could be shortened. The laser beam cutting would therefore represent a much cheaper alternative for the dismantling of the reactor components.

About AZULa:

The project “Automated separation of reactor pressure vessel installations using underwater laser technology” (AZULa) is carried out together with the Orano GmbH. AZULa is sponsored by the Federal Ministry of Education and Research (BMBF) under grant number 15S9408 by the project coordinator Gesellschaft für Anlagen- und Reaktorsicherheit gGmbH (GRS).

There are two figures for this press release.

Laser Zentrum Hannover e.V.

Dipl.-Biol. Lena Bennefeld

Abteilung Kommunikation

Hollerithallee 8

D-30419 Hannover

Germany

Tel.: +49 511 2788-238

Fax: +49 511 2788-100

E-mail: l.bennefeld@lzh.de

Internet: www.lzh.de

Media Contact

All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…