Thin films from Braunschweig on the way to Mercury

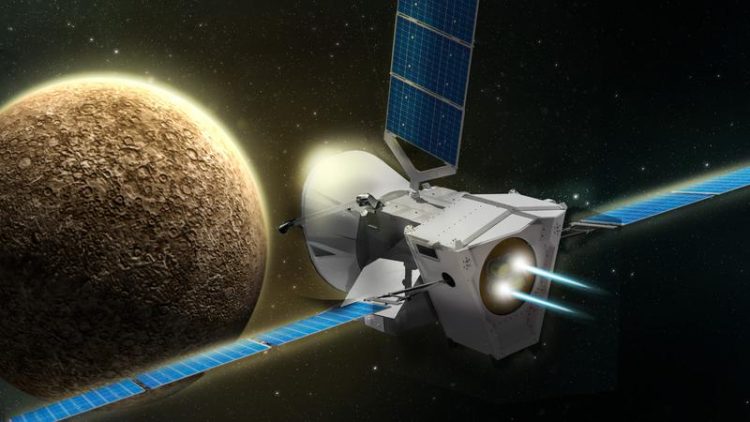

The Mercury probe BepiColombo. Airbus

Mercury is the smallest planet of our solar system, and it is closest to the sun at a distance of only about 58 million kilometers. As a result, the temperatures on the surface fluctuate extremely, the maximum temperatures are up to 430 °C, the lowest temperatures down to -173 °C.

The research probe BepiColombo, which was developed under the leadership of Airbus, not only has to survive the long flight to Mercury, but also has to deliver reliable data for more than a year despite the most extreme conditions.

One of the measures to protect against excessive temperatures are cooling fins made of titanium and coated with silver. A direct galvanic silvering of titanium is very complex: To adhere the films, the titanium must be etched with hydrofluoric acid or other fluorine-containing chemicals.

In addition, there is a risk that the material becomes brittle. More environmentally friendly and material-saving is the solution of the Fraunhofer IST, where the titanium parts are coated with a very thin and adhesive copper film in a vacuum using a plasma process.

”The titanium components we coppered were then successfully silver plated by a partner in a rather simple galvanic process and are ready for the mission,” explains IST project manager Ralf Wittorf.

To ensure that both coating processes and coatings meet the highest requirements, the entire production chain for the coating deposition at the Fraunhofer IST has been developed and optimized.

”Thanks to the combination of plasma technology and electroplating, the overall process has been considerably simplified,” revel Wittorf and his colleague Torsten Hochsattel. With excitement and, of course, a little pride, the persons involved look forward to the start of the mission and hope for no interferences. ”I will definitely set my alarm clock,” says Hochsattel.

About BepiColombo

BepiColombo is a joint project of the European space agency ESA and the Japanese space agency JAXA, realized by Airbus, heading an international consortium of 83 companies from 16 countries. BepiColombo aims to explore the peculiarities of the internal structure of Mercury and its magnetic field as well as the interaction of the magnetic field with the solar wind. The probe will evaluate the properties and chemical composition of the planetary surface and investigate whether ice exists in the craters, that are averted from the sun in the polar regions.

Dr. Simone Kondruweit

https://www.ist.fraunhofer.de/en/press_media/2018/thin-films-from-braunschweig-t…

https://www.ist.fraunhofer.de/en/press_media/2018/thin-films-from-braunschweig-t…

Media Contact

All latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…