Significantly more productivity in USP lasers

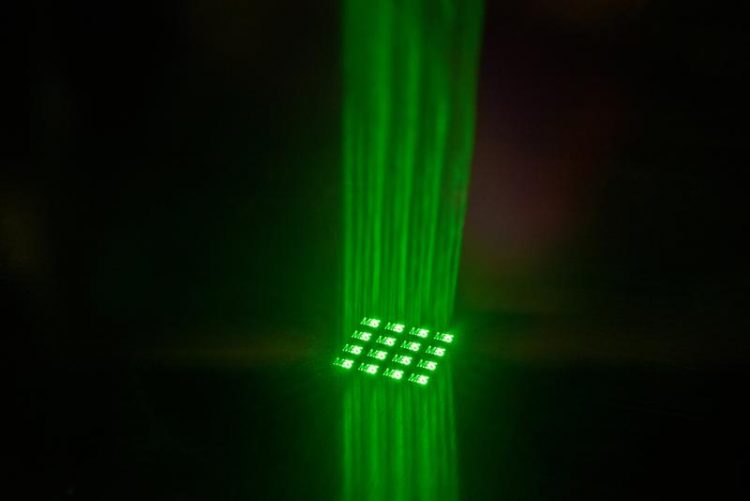

With the hybrid systems composed of freely programmable multi-beam optics and galvo scanners, a laser beam can be split into any number of beamlets. © Fraunhofer ILT, Aachen, Germany / Volker Lannert.

Even back in the 1990s, scientists were comparing materials processing with nanosecond, picosecond and femtosesecond pulses. The result was surprising: Ultrashort pulses vaporize the material so rapidly that hardly any heat remains in the workpiece. At the same time, surfaces are particularly smooth, cuts extremely precise and the process is barely dependent on the used material.

This has been recognized for a long time, but it is only in the last ten years that complex laser sources have reached a level that permits 24/7 use in industry. Systems with up to 100 watts are now being sold in batches.

These systems have become established in micro-material processing, with calls in the meantime for more productivity and stronger lasers. The development of laser sources with kW power is well advanced, but a simple scaling of processes by increasing the laser power is not immediately possible without losing the high processing quality – process engineering especially beam delivery is now the bottleneck.

Which is faster? Scanners versus multi-beam optics

New USP laser sources offer improved performance through repetition rates into the MHz range or through higher pulse energies. New scanner systems with polygon mirrors show promising results for high repetition rates. In this context, the spot must be moved extremely rapidly on the workpiece to keep too many pulses from overlapping and the accumulated heat from impairing the processing quality.

Scanners enable a high level of flexibility in the contour to be processed, but they move only a single spot on the surface of the workpiece. Large surfaces with repeating patterns can be processed more efficiently with what are known as multi-beam optics.

A multi-beam optic device splits a single laser beam into numerous beamlets. This requires higher laser pulse energies so that every beamlet can also remove material. Micro-optics or diffractive optical elements that generate a set pattern from a laser beam have been tested to date. Adjusted to the application, this might be a line, a special contour or a pattern made of hundreds of single beams.

Dynamic multi-beam optics uses liquid crystals

At present, beam shaping in multi-beam optics is achieved by diffracting the laser beam on solid optical structures. Experts at Fraunhofer ILT in Aachen have now developed a system that allows the diffractive pattern to be switched at a rate of 50 hertz. To this end, they use spatial light modulators (SLM) that generate the required diffraction pattern with liquid crystals.

The researchers optimized the system and tested it together with a galvanometer scanner in an experimental setup. With suitable optics, image errors are corrected so that even large workpieces can be processed with a high degree of precision.

Programmable multi-beam optics enable a significant increase in productivity, especially in USP lasers with higher pulse energies. Applications are envisioned in microelectronics or in the texturing of surfaces, in the consumer goods sector for example.

4th UKP Workshop 2017

Productivity and process engineering when using USP lasers will be important topics at the “UKP Workshop – Ultrafast Laser Technology” on April 26 and 27, 2017 in Aachen, Germany. Specialists from laser development, process engineering and industry will be meeting there for the fourth time to discuss new results and share experience gained from practice. You will find more information on the event at www.ultrakurzpulslaser.de.

Contact

Dipl.-Phys. Patrick Gretzki

Micro and Nano Structuring Group

Telephone +49 241 8906-8078

patrick.gretzki@ilt.fraunhofer.de

http://www.ilt.fraunhofer.de/en.html

http://www.ultrakurzpulslaser.de/en

Media Contact

All latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…