James Webb Space Telescope's laser-focused sight

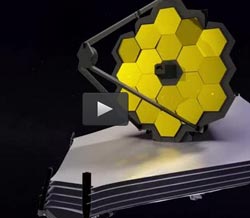

Artist rending showing light reflecting off of the primary and secondary mirrors of NASA's James Webb Space Telescope, after it has deployed in space. Credits: NASA/M. McClare

Though the Webb telescope will focus on stars and galaxies approximately 13.5 billion light-years away, its sight goes through a similar process as you would if you underwent laser vision correction surgery to be able to focus on an object 10 feet across the room.

In orbit at Earth's second Lagrange point (L2), far from the help of a terrestrial doctor, Webb will use its near-infrared camera (NIRCam) instrument to help align its primary mirror segments about 40 days after launch, once they have unfolded from their unaligned stowed position and cooled to their operating temperatures.

Laser vision correction surgery reshapes the cornea of the eye to remove imperfections that cause vision problems like nearsightedness. The cornea is the surface of the eye; it helps focus rays of light on the retina at the back of the eye, and though it appears to be uniform and smooth, it can be misshapen and pockmarked with dents, dimples, and other imperfections that can affect a person's sight.

The relative positioning of Webb's primary mirror segments after launch will be the equivalent of these corneal imperfections, and engineers on Earth will need to make corrections to the mirrors' positions to bring them into alignment, ensuring they will produce sharp, focused images.

These corrections are made through a process called wavefront sensing and control, which aligns the mirrors to within tens of nanometers. During this process, a wavefront sensor (NIRCam in this case) measures any imperfections in the alignment of the mirror segments that prevent them from acting like a single, 6.5-meter (21.3-foot) mirror.

An eye surgeon performing wavefront-guided laser vision correction surgery (a process that was improved by technology developed to shape Webb's mirrors) similarly measures and three-dimensionally maps any inconsistencies in the cornea. The system feeds this data to a laser, the surgeon customizes the procedure for the individual, and the laser then reshapes and resurfaces the cornea according to that procedure.

Engineers on Earth will not use a laser to melt and reshape Webb's mirrors (feel free to give a sigh of relief); instead, they will use NIRCam to take images to determine how much they need to adjust each of the telescope's 18 primary mirror segments. They can adjust the mirror segments through extremely minute movements of each segment's seven actuators (tiny mechanical motors) — in steps of about 1/10,000th the diameter of a human hair.

The wavefront sensing and control process is broken into two parts — coarse phasing and fine phasing.

During coarse phasing, engineers point the telescope toward a bright star and use NIRCam to find any large offsets between the mirror segments (though “large” is relative, and in this case it means mere millimeters). NIRCam has a special filter wheel that can select, or filter, specific optical elements that are used during the coarse phasing process. While Webb looks at the bright star, grisms in the filter wheel will spread the white light of the star out on a detector. Grisms, also called grating prisms, are used to separate light of different wavelengths. To an observer, these different wavelengths appear as parallel line segments on a detector.

“The light from each segment will interfere with adjacent segments, and if the segments are not aligned to better than a wavelength of light, that interference shows up like barber pole patterns,” explained Lee Feinberg, optical telescope element manager for the Webb telescope at NASA's Goddard Space Flight Center in Greenbelt, Maryland. “The analysis of the barber pole patterns tell the engineers how to move the mirrors.”

During fine phasing, engineers will again focus the telescope on a bright star. This time, they will use NIRCam to take 18 out-of-focus images of that star — one from each mirror segment. The engineers then use computer algorithms to determine the overall shape of the primary mirror from those individual images, and to determine how they must move the mirrors to align them. These algorithms were previously tested and verified on a 1/6th scale model of Webb's optics, and the real telescope experienced this process inside the cryogenic, airless environment of Chamber A at NASA's Johnson Space Center in Houston. Engineers will go through multiple fine-phasing sessions until those 18 separate, out-of-focus images become a single, clear image.

After the engineers align the primary mirror segments, they must align the secondary mirror to the primary, then align both the primary and secondary mirrors to the tertiary mirror and the science instruments. Though the engineers complete the initial alignment with NIRCam, Feinberg explained they also test the alignment with Webb's other instruments to ensure the telescope is aligned “over the full field.”

The entire alignment process is expected to take several months, and once Webb begins making observations, its mirrors will need to be checked every few days to ensure they are still aligned — just as someone who underwent laser vision correction surgery will schedule regular eye doctor visits to make sure their vision is not degrading.

The James Webb Space Telescope, the scientific complement to NASA's Hubble Space Telescope, will be the premier space observatory of the next decade. Webb is an international project led by NASA with its partners, ESA (European Space Agency) and CSA (Canadian Space Agency).

###

For more information about the Webb telescope visit: http://www.

Media Contact

All latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…