Fast and Ultra-precise: Processing Optics with LBF

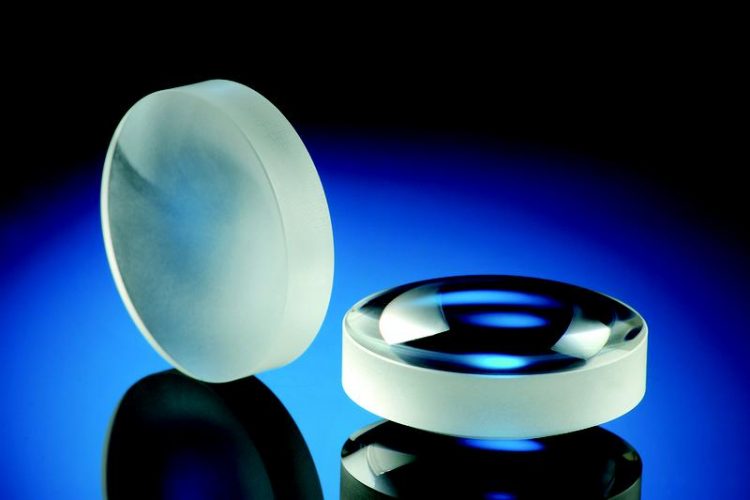

The LBF process is particularly suitable for the correction of non-spherical optics in small to medium quantities. © Fraunhofer ILT, Aachen, Germany.

Thanks to their good imaging properties, aspheres are the dream of many optical designers. Aspheres have one great disadvantage, however: mechanical processing, which is much more time-consuming than for conventional spherical optics. And for a high surface quality, a special post-treatment is often necessary.

Laser polishing is a first step towards simplifying this surface finishing issue. In laser polishing, the glass surface is heated with CO2 laser radiation to just below the evaporation temperature. The viscosity of the surface sinks, the roughness flows out and the surface is smoothed.

This way, the micro-roughness can be improved quickly.

For periodic structures with a wavelength of more than 100 μm, which can occur during mechanical processing, laser polishing is not enough. This requires ultra-precise ablation processes.

Laser Beam Figuring

For ultra-precision machining with a few nanometers’ removal, Ion Beam Figuring (IBF) and Magnetorheological Finishing (MRF) have been the methods of choice. The experts at Fraunhofer ILT have now developed a laser-based method that can work more accurately and faster.

In Laser Beam Figuring (LBF), a pulsed CO2 laser removes glass material from the surface. The ablation rate can be precisely controlled by regulating the pulse duration. The lateral resolution of the ablation is essentially determined by the size of the laser spot. For example, a vertical resolution of less than 5 nm and a lateral resolution of less than 100 μm are possible during ablation.

Unlike the IBF, the LBF process does not require a vacuum; nor does it need any additional fluids, unlike MRF. At the same time, LBF enables maximum flexibility in shaping, as the non-contact process works on surfaces of almost any shape.

First Continuous Laser-based Process Chain in Optics Production

With LBF, Fraunhofer ILT has created the first continuous laser-based process chain in optical production. In a first step, the material is removed relatively coarsely for an individual shape. Then the surface is polished with the laser. For the final shape correction then the LBF is used.

Thanks to its speed and flexibility in surface design, the LBF process is particularly well suited for cost-effective shape correction of non-spherical optical components in small to medium quantities. In addition to aspheres, micro-optics can also be processed. The laser shape correction can be combined with both laser polishing and conventional machining methods.

The work has been funded by the Federal Ministry of Education and Research (BMBF), among others, as part of the RapidOptics project under grant number 13N13294.

Fraunhofer ILT will be presenting the LBF process and other laser-based technologies for optical production from May 15 to 17 at Optatec in Frankfurt. You will find the Fraunhofer Joint Stand F14 in Hall 3.0.

Contact

Christian Weingarten M. Sc.

Group Polishing

Telephone +49 241 8906-282

christian.weingarten@ilt.fraunhofer.de

Dr.-Ing. Edgar Willenborg

Group Manager Polishing

Telephone +49 241 8906-213

edgar.willenborg@ilt.fraunhofer.de

Media Contact

More Information:

http://www.ilt.fraunhofer.deAll latest news from the category: Physics and Astronomy

This area deals with the fundamental laws and building blocks of nature and how they interact, the properties and the behavior of matter, and research into space and time and their structures.

innovations-report provides in-depth reports and articles on subjects such as astrophysics, laser technologies, nuclear, quantum, particle and solid-state physics, nanotechnologies, planetary research and findings (Mars, Venus) and developments related to the Hubble Telescope.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…