Artificial pericardial tissue from the 3D printer

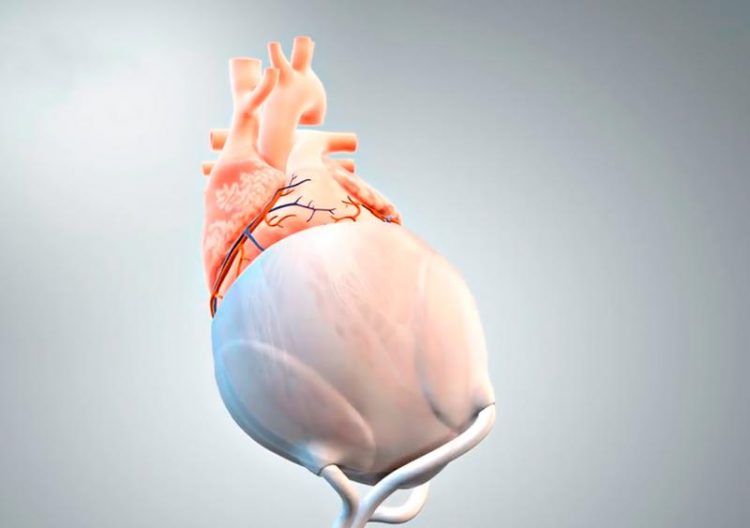

The first application of the pericardium replacement material is to produce a new type of surface for an extravascular cardiac support system using 3D printing. © AdjuCor GmbH

The PolyKARD partners – AdjuCor GmbH, the Fraunhofer Institute for Applied Polymer Research IAP, the NMI Natural and Medical Sciences Institute, Young Optics Europe GmbH and pro3dure medical GmbH – plan to advance the production of the implants until the first clinical studies, probably in 2022.

Heart disease is one of the most frequent cause of death. Approximately 23 million people worldwide suffer from cardiac insufficiency ̶ and the number is increasing. In contrast, the number of heart transplants is stagnating at about 3000 transplants per year worldwide.

Artificially produced implants could help many patients who are waiting for a donor organ. The 3D printing of precisely fitting implants has become indispensable in medicine, for example in orthopedics or dental surgery.

However, there is a much greater need for research into implants that are intended to replace elastic tissue, because the demands on the materials are high: they must retain their mechanical properties for many years, be 100 percent resistant and biocompatible, and must not cause rejection reactions by the immune system.

The latter is particularly important for materials that are permanently in contact with the body.

New polymers for modern printing technologies and individual medical technology

In the PolyKARD project, biomimetic polymers are being developed to mimic the biological and mechanical material properties of the pericardium. The pericardium is a collagen-containing and mechanically extremely stable structure that surrounds the heart. Clinically, the pericardium of cattle or pigs is already used to replace human heart valves or to reconstruct blood vessels.

However, the processing of animal tissue is expensive and does not guarantee long-term mechanical stability. Other problems include the unreliable quality due to the great variability between donor animals as well as ethical and religious aspects.

“In this project, we are developing biomimetic pericardial replacement materials that can be used, for example, for artificial pericardium, heart valves, blood vessels, stents, tendons or septum occlusions. The special feature of these implants is that they are made of photopolymers and can be produced individually using a 3D printer or electrospinning.

The monomers are developed as inks or resins. They only polymerize when they are irradiated with UV light”, explains Dr. Wolfdietrich Meyer, who heads the project at the Fraunhofer IAP in Potsdam. The research team at the Fraunhofer IAP is synthesizing a photocrosslinkable material consisting of different polyurethane segments and collagen components.

Elastic, biocompatible and resistant

The newly synthesized polymers are tested for in vitro cytotoxicity at the NMI in Reutlingen according to DIN EN ISO 10993-5. The polymers are processed using different 3D printing methods and electrospinning. At the NMI, this spinning process is used to create porous structures that can grow together with the patient's own body tissue.

The carrier substrates produced are characterized in terms of their mechanical and biological properties. Special emphasis is placed on the reproduction of the mechanical properties of the pericardium and the growth behavior of cells.

The first application of the biomimetic polymer will be the printing of a novel surface for an extravascular cardiac support system. The system of the Munich-based AdjuCor GmbH is based on a patient-specific mechanical implant, which is positioned completely outside the blood flow (extravascular) in the pericardial cavity around the epicardial surface of both heart chambers.

“A biomimetic pericardial replacement material would cause only minor immune reactions and would thus lead to a gentle healing phase. This could further shorten intensive care and hospital stays”, explains heart surgeon and CEO of AdjuCor Prof. Stephen Wildhirt.

On the way to marketability

In order to be approved for clinical applications on the market in the future, both the new photopolymers and the processing methods must meet extensive requirements. For the large-scale production of photopolymers, the GMP (Good Manufacturing Practice) guidelines must be observed.

They ensure the quality of the production processes and environment. The company pro3dure medical GmbH Iserlohn will establish the upscaling process of the photopolymers as well as the resin synthesis under consideration of these GMP.

Young Optics Europe GmbH in Jena processes previously biocompatible photopolymers for products of medical classes I – IIa with the 3D printers they have developed.

Within the PolyKARD project, a 3D printing system for the production of class III medical products is to be established for the first time, which will also enable complete traceability of the raw materials used for production.

Using holistic chemistry to create new materials

The three-year PolyKARD project started in April 2019 and is being implemented by the VDI Verein Deutscher Ingenieure e.V. as project management agency, on behalf of the BMBF under the funding measure “Material Innovations for Healthy Living: ProMatLeben – Polymers” (FKZ: 13XP5087D). The partners will meet again on 4 February 2020 to present first milestones. ” We have already successfully synthesized and printed the first elastic photourethane resins from non-toxic starting materials”, explains Wolfdietrich Meyer.

“In the future, we would like to apply the medical concept of wholeness even more strongly to our chemistry. We want to develop more materials based on renewable raw materials for 3D printing and electrospinning that are biocompatible and can be processed with the highest precision. We are also keeping an eye on the life cycle of the component and, if necessary, environmentally friendly disposal,” says Meyer.

https://www.iap.fraunhofer.de/en/press_releases/2020/artificial-pericardial-tiss…

Media Contact

All latest news from the category: Health and Medicine

This subject area encompasses research and studies in the field of human medicine.

Among the wide-ranging list of topics covered here are anesthesiology, anatomy, surgery, human genetics, hygiene and environmental medicine, internal medicine, neurology, pharmacology, physiology, urology and dental medicine.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…