Scientists develop recyclable plastics

Light controls different wavelengths Copyright: Fabian Eisenreich

A research team from Berlin has developed a novel catalyst system, which enables the regulation of multiple polymerization processes to produce biodegradable plastics solely by illumination with light of different colors. The results of this work have now been published in Nature Catalysis.

The properties of a polymeric material are highly dependent on factors, such as the connected monomer building blocks as well as the length and composition of the formed polymer chains. Typically, these factors are predetermined by the choice of the employed reaction conditions.

In order to overcome this limitation and generate materials with new and unprecedented properties, regulation of polymerizations by means of external stimuli represents an attractive goal. Similarly to dental repair, light serves to precisely control the location and duration of the chemical reaction during polymer formation.

A new method for the light-regulated production of biodegradable polymers has now been developed by chemists of the Humboldt-Universität zu Berlin (HU), the Federal Institute for Materials Research and Testing Berlin, and the Heinrich-Heine-Universität Düsseldorf.

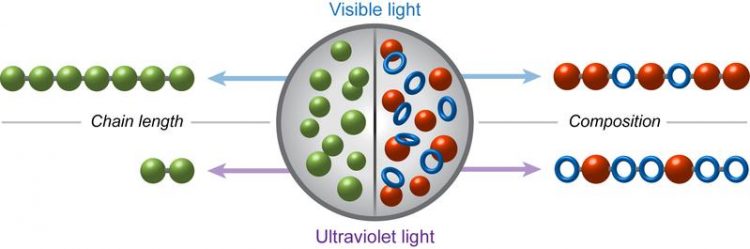

Their work is based on the design of a unique catalyst, which is capable to change its activity reversibly by illumination with light of different wavelength. Using their catalyst, the scientists were able to turn the formation of polylactide on and off on demand, which allowed them to control the chain length of the produced polymer strands. Moreover and for the first time, they were able to regulate the incorporation of two different monomers into the same polymeric backbone with light.

Fabian Eisenreich and Michael Kathan from the department of chemistry at the HU and first authors of the study explain: “With our remote-controlled catalyst we are in principle able to program the formation of a desired polymer strand by employing a specific order and duration of light pulses.”

Their promising development is an important step toward smart production processes of (biodegradable) polymers with the aim to meet the growing demands of future applications, including light-guided 3D printing.

Publication

“A photoswitchable catalyst system for remote-controlled (co)polymerization in situ”

In: Nature Catalysis (2018), DOI: 10.1038/s41929-018-0091-8

Authors: Fabian Eisenreich, Michael Kathan, Andre Dallmann, Svante P. Ihrig, Timm Schwaar, Bernd M. Schmidt and Stefan Hecht

https://www.nature.com/articles/s41929-018-0091-8

Visualization

Copyright: Fabian Eisenreich

Descrition: With the aid of a photoswitchable catalyst both chain length (left) as well as composition (right) of the formed polymers can be controlled by light of different wavelengths.

Further Information

http://www.hechtlab.de

http://www.iris-adlershof.de

Contact

Prof. Stefan Hecht, Ph.D.

Department of Chemistry / IRIS Adlershof

+49 30 2093-7365

sh@chemie.hu-berlin.de

Media Contact

More Information:

http://www.hu-berlin.de/All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…