Pearls to Prevent Relaxation

Putting a stop to aging has now been made possible for highly porous polymer membranes whose efficiency in the separation of gases falls off fast when parts of their polymer chains rearrange, as so do their pores.

In the journal Angewandte Chemie , a team of Australian and American researchers has now introduced a method for preventing this relaxation of the polymer chains: special porous particles made of an aromatic framework incorporate the polymer chains and hold them in their original position.

Separation processes like purification and adsorption are especially energy-intensive procedures; it is thus correspondingly important to find alternatives to replace existing technologies.

One possible approach is gas separation using polymer membranes. The theory behind this separation technique is that different gases pass through the membrane at different rates. This allows for the separation of CO2 from nitrogen, for example, which is relevant for carbon capture from flue gases. Currently, liquid absorbents that operate in a batch rather than continuous process are typically used.

The polymer membranes used must be extremely porous, so that as much of the surface area as possible is accessible to the gas molecules. It is no problem to produce highly porous membranes by using the appropriate “molds”.

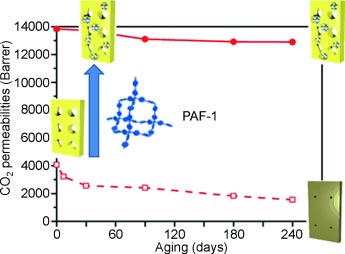

However, any celebration of the high separation performance of these super glassy membranes, as they are known, does not last long as the membranes “age”. Despite the rigid state of the polymer, individual polymer segments are not fully “frozen” into position but can move to some extent. For thermodynamic reasons, the polymer chains attempt to stay as evenly distributed as possible.

This also causes them to fill the empty space within the pores. Because of their residual mobility, the polymer chains “relax” little by little, slowly reducing the free volume of the pores. The separation performance of the membrane falls off correspondingly. It has not previously been possible to effectively halt this process.

Led by Matthew R. Hill and Richard D. Noble, a team from the Division of Materials Science and Engineering at the Commonwealth Scientific and Industrial Research Organization (CSIRO) and the University of Colorado (USA) has now developed a method that prevents aging of super glassy membranes.

The trick is to include a specific additive during production of the membranes. The additive consists of porous microparticles made of a special three-dimensional framework of aromatic compounds and carbon atoms. The microparticles are strung along the particle chains like pearls on a string. This causes the chains to be “frozen” in place.

The pores remain as open as they were when first manufactured and the membrane does not age. As a side effect, the porous aromatic microparticles improve the ability of the membranes to separate nitrogen and carbon dioxide up to three-fold.

About the Author

Dr. Matthew Hill is a senior research scientist with the CSIRO, Australia’s national science agency. He specialises in ultraporous materials with applications in separation, storage and triggered release. He is a 2014 awardee of the MIT Technology Teview ‘Innovators under 35’ award for the South-East Asia region.

Author: Matthew R. Hill, CSIRO Division of Materials Science and Engineering, Clayton South (Australia), https://wiki.csiro.au/display/MEWE/Matthew+Hill

Title: Ending Aging in Super Glassy Polymer Membranes

Angewandte Chemie International Edition, Permalink to the article: http://dx.doi.org/10.1002/anie.201402234

Media Contact

More Information:

http://pressroom.angewandte.orgAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…