Diagnostics for everyone

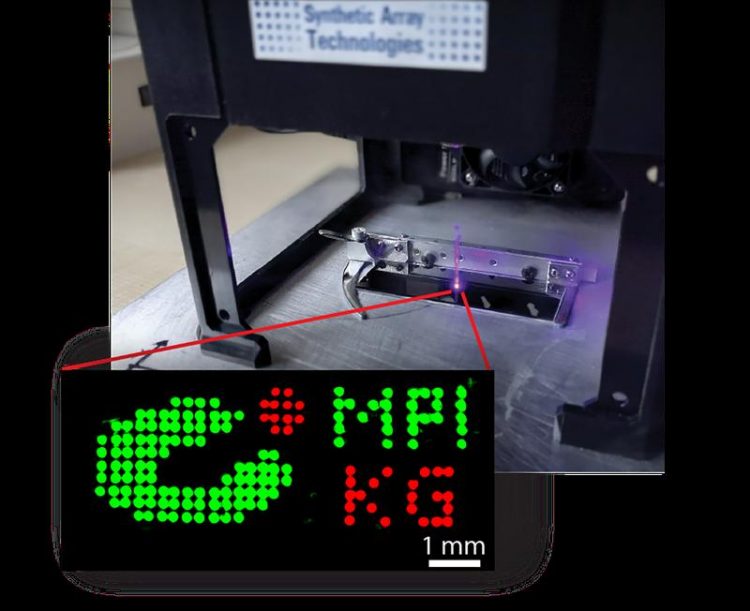

Production of a microarray with the cost-effective DIY setup. A laser from a Blu-ray player accurately transfers minute amounts of biomolecules to a surface with up to 2 500 spots per square cm². Max Planck Institute of Colloids and Interfaces

Microarrays are state-of-the-art tools in molecular biology that enable the rapid and parallel diagnosis of various diseases. Therefore, they are indispensable for the development of new vaccines. Like a computer chip, microarrays contain a lot of information in the smallest space.

Microarrays contain thousands of different biomolecules on a surface of a few square centimeters, which can be analyzed in a single experiment. The production of such microarrays has been very expensive and required complex machinery.

Cost-effective, laser-based method

Therefore, the research group of Felix Loeffler develops cost-effective processes and researches novel technologies for the chemical production of microarrays. Similar to the principle of a typewriter, a laser can transfer small polymer nanosheets, containing certain colors or chemical building blocks, in finely defined dot patterns.

Subsequently, these molecules can chemically react to complex artificial structures, representing, for example, parts of a pathogen. These microarrays are then used for vaccine research or blood testing. So far, however, this technique could only be used by a few specialists.

DIY microarrays

In a collaboration of the departments of “Biomolecular Systems” and “Colloid Chemistry”, Eickelmann et al. present a cost-effective approach to generate microarrays and show a first application in carbohydrate research. Based on a low-cost commercial laser engraver, employing simple components of consumer electronics (Blu-ray player), they developed a very simple system.

In addition, they made a spin coater from remaining components, which serves to produce the (color) donor surfaces. Thus, all steps for microarray production can now be performed in any chemistry lab in the world without any special equipment. The total cost of this system is less than 200 euros, which is 200 times cheaper than a conventional device.

Felix Löffler, senior scientist, emphasizes: “The principle is suitable for many different applications and also offers great potential for basic research. It is suitable for the parallel development of new chemical reactions, as well as, for use in disease research, for the synthesis of proteins, sugars, and DNA.”

Stephan Eickelmann, Alexandra Tsouka, Jasmin Heidepriem, Grigori Paris, Junfang Zhang, Valerio Molinari, Marco Mende, Felix F. Loeffler:

A Low‐Cost Laser‐Based Nano‐3D Polymer Printer for Rapid Surface Patterning and Chemical Synthesis of Peptide and Glycan Microarrays

Advanced Materials Technologies(2019)

Media Contact

More Information:

http://www.mpikg.mpg.deAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…