Converting biomass by applying mechanical force

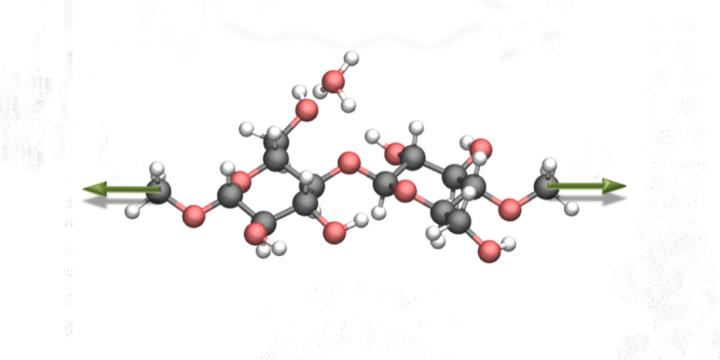

The molecular structure of cellulose, to which nanoscientists applied mechanical force (green arrows). The hydrolysis reaction changed dramatically as a result. Credit: Saeed Amirjalayer et al./Angew Chem Usage Restrictions: The pictures may only be used in connection with the press release.

One of the greatest global challenges is the efficient use of renewable sources in order to meet the increasing demand for energy and feedstock chemicals in the future. In this context, biomass is a promising alternative to existing fossil sources such as coal or oil.

Cellulose plays a decisive role here because it accounts for the largest fraction of the natural carbon storage. These reservoirs are crucial for the production of both fuels and basic chemicals.

In order to utilize its full potential, the chain-like structure of cellulose must be broken up. This can be done by a so-called hydrolysis reaction, which, however, is difficult due to the atomic structure of cellulose and has been very costly so far.

Researchers at the University of Münster (Germany) headed by Dr. Saeed Amirjalayer and Prof. Harald Fuchs and and the University of Bochum headed by Prof. Dominik Marx have now succeeded in identifying a new reaction mechanism in which cellulose can be converted highly efficiently using mechanical force.

This so-called mechano-catalytic reaction could lead to the development of an efficient, environmentally friendly and cost-effective process for the conversion of biomass. The study has been published in the journal Angewandte Chemie International Edition.

Background information and Method:

Using a hydrolysis reaction, the cellulose backbone can be broken down into individual molecular building block. These molecular building blocks are the actual basis for producing fuels or chemical feedstocks. In their search for ways to make the hydrolysis reaction more efficient, researchers have already found evidence in earlier studies that mechanical forces can influence the process of conversion.

So-far it has not been possible to elucidate the influence of mechanical force during each individual reaction step at the atomic level. However, this level of insight is needed to develop a corresponding efficient and resource-efficient process. In the now published work, the scientists show that the use of mechanical force on the cellulose molecules, over a certain level, has a significant influence on the reaction.

To do so, the nanoscientists carried out so-called atomistic modelling. These enabled them to follow the individual steps of the hydrolysis reaction in detail and at the same time to apply a mechanical force on the molecular structure.

The researchers calculated so-called energy profiles, which describe the energy pathway along the reaction coordinate with and without the influence of mechanical forces. What they succeeded to show is that stressing the molecular backbone of the cellulose had a strong influence on the hydrolysis reaction. On the one hand, the energy required to activate the process was significantly reduced.

On the other hand, an increased mechanical force even made two of the usual three reaction steps superfluous. “By means of our atomistic models we could explicitly investigate the influence of mechanical force on the reaction mechanism”, says leading author Dr. Saeed Amirjalayer, who works as a group leader at the Institute of Physics at Münster University and at the Center for Nanotechnology (CeNTech). “This enabled us to elucidate a previously unknown and highly efficient reaction pathway for the conversion of cellulose,” he adds.

The new results not only confirm the experimental observations, but also show the potential to control molecular processes with the help of mechanical force. “Among other things, we were able to show that the so-called proton affinity in cellulose can be increased region-selectively by mechanical force,” Saeed Amirjalayer explains.

The scientists therefore hope that this work will not only enable an efficient and environmentally friendly process for the conversion of cellulose, but also lead to the development of novel mechano-responsive substances, such as plastics. These substances could be easily recycled by mechanical forces after usage.

###

Original publication:

S. Amirjalayer, H. Fuchs, D. Marx: Understanding the Mechanocatalytic Conversion of Biomass: A Low Energy One Step Reaction Mechanism by Applying Mechanical Force, Angewandte Chemie Int. Ed. (2019)

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…