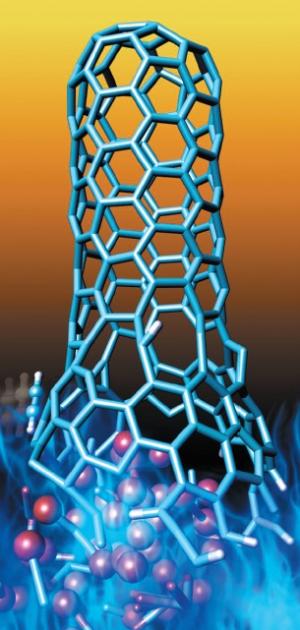

Carbon nanotubes grown in combustion flames

Copyright : Institute of Transformative Bio-Molecules (ITbM), Nagoya University

The synthesis of carbon nanotubes (CNTs), with a view to their industrial-scale production, is attracting heavy scientific interest. Their unique chemical properties promise a wide variety of groundbreaking uses in acoustic, biomedical, electronic, environmental, optical and structural technologies.

Led by Professor Stephan Irle of the Institute of Transformative Bio-Molecules at Nagoya University, a team of researchers in Japan, the United States and China conducted computer simulations that show similar molecular mechanisms at work in the growth of carbon nanotubes and the combustion of hydrocarbons to form soot. This discovery challenges a previously accepted view that metal carbides are needed to create nanotubes, through a process called chemical vapour deposition.

The team’s own models suggest that alternative chemical processes such as hydrogen- bstraction/acetylene addition – a mechanism often observed in combustion processes – could also be used to grow carbon nanotubes. “This finding is very intriguing in the sense that these processes were long considered to proceed by completely different mechanisms,” says Professor Irle.

In 2014, the team reported the first growth simulations of single-walled carbon nanotube synthesis, using acetylene as a feedstock. Their simulation model used acetylene due to the relatively low temperatures needed to catalyse chemical vapour deposition, and because even small amounts speed up reactions significantly. According to the researchers, their modelling suggests that acetylene’s potential role needs further study, as does the currently accepted model for carbon nanotube production.

Since publishing their results, the researchers have started modelling the synthesis of graphene – a one atomthick layer of pure carbon – using nickel and copper with a methane catalyst. They hope to publicly release the new simulation model – based on a direct version of a kinetic Monte Carlo simulation where reaction channels are predicted automatically on the fly as the growth process proceeds – in 2015.

DID YOU KNOW?

Carbon nanotubes are nanocylinders consisting of one atom-thick sheets of carbon (or graphene). They are currently used as additives to strengthen various structural materials, and may also be used for energy storage as well as in the next generation of nanoelectronics and biomedical devices. CNTs are often synthesised via chemical vapour deposition, in which hydrocarbon vapour is deposited on metal catalysts under a flow of non-reactive gas at high temperatures. However, quality control is a challenge since this method usually results in the production of CNTs with variable diameters and different sidewall structures.

For further information contact:

Professor Stephan Irle

Institute of Transformative Bio-Molecules

World Premier International Research Center Initiative

Nagoya University, Japan

E-mail: sirle@chem.nagoya-u.ac.jp

Institute of Transformative Bio-Molecules (ITbM), Nagoya University

*This article also appears in Asia Research News 2015 (P.61).

Associated links

Read Asia Research News 2015

Download a copy of Asia Research News 2015 for free

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…