Robotics in care: DFKI Bremen and Johanniter work on the hospital bed of the future in BMBF-funded project

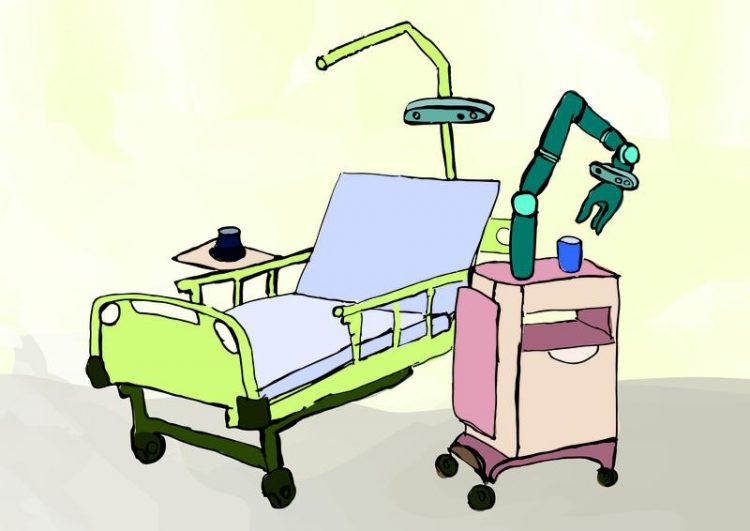

Visualization of the employment of a robot arm for the support of patients with physical limitations. Source: DFKI GmbH, Graphic: Annemarie Popp

The care industry in Germany is facing numerous challenges: Apart from a continuing shortage of staff, the strains on medical workers have also been increasing – and not only in recent times.

The daily work with people in need of care that also require support in their everyday life puts a burden on the physical health of nursing staff and causes illness, sick leaves and even occupational disabilities.

For this reason, the German Federal Ministry of Education and Research (BMBF) funds the project AdaMeKoR, which searches for solutions in order to relief medical workers and create more autonomy for patients at the same time.

At the centre of the research project, which started on 15 March 2020, lies the development of the equipment for the hospital bed of the future, including a robot arm and sensors for the control of the right use.

Coordinated by the Johanniter-Unfall-Hilfe humanitarian organisation, the universities of Osnabrueck and Oldenburg and the DFKI work on different components that can turn a hospital bed into a system of relief for nursing staff and patients.

With the Robotics Innovation Center and the Cyber-Physical Systems research departments, the entire DFKI location in Bremen is participating in the project.

A robot arm as a third hand for physically limited patients

As part of the project, the Carl von Ossietzky University of Oldenburg is working on a robot arm for transferring patients as well as sensors that analyze the posture of care workers. The DFKI is concentrating on the handling of the robotic support as well as mobilization.

This involves on the one hand a robot arm with which people with physical limitations can live more independently, and on the other hand concepts for the support of the ability to move and the transfer of patients between bed and wheelchair with the help of robotic devices.

The Cyber-Physical Systems research department, led by Prof. Dr. Rolf Drechsler, is working on control mechanisms for a Kinova robot arm that allow the arm to be used with easily manageable systems such as a joystick.

The arm can be used as a third hand for people with limited mobility. For this, the robot arm is installed on a bedside stand, from where it is controlled with a joystick or a more complex 3D mouse and can help reaching objects.

Robotic concepts for the transfer to the wheelchair – even with higher weight

At the Robotics Innovation Center, led by Prof. Dr. Dr. h.c. Frank Kirchner, concepts are developed that allow for a supported transfer of patients – for instance from the bed to a wheelchair, which is a great physical strain for medical workers.

Robotic solutions can be a remedy for this, especially when they can also safely handle people of a higher weight, are easy to be used and can be integrated seamlessly in the everyday life of medical staff. The most promising concepts will be visualized on the computer for a possible realization.

The project aim is a demonstrator that presents the possibilities of a robotic, sensoric and partially automated support in handling patients. The physical relief and the posture control of nursing staff as well as the improved autonomy of patients are meant to increase the health and the life quality of the two respective target groups.

For this reason, the German Federal Ministry of Education and Research (BMBF) funds the project AdaMeKoR for a runtime of three years with a total of 1.8 million Euros, of which roughly 623,000 Euros go to the DFKI.

Press material:

At https://cloud.dfki.de/owncloud/index.php/s/SzKW5qKnJsmqHWb you can find a visualization of the project. You may use this image naming the source “DFKI GmbH, Graphic: Annemarie Popp”.

Contact CPS:

Dr. Serge Autexier

German Research Center for Artificial Intelligence (DFKI)

Cyber-Physical Systems

Phone: +49 421 218 98 59834

Mail: Serge.Autexier@dfki.de

Contact RIC:

Niels Will

German Research Center for Artificial Intelligence

Robotics Innovation Center

Phone: +49 421 17845 6660

Mail: Niels.Will@dfki.de

Press contact:

German Research Center for Artificial Intelligence

Team Corporate Communications Bremen

Phone: +49 421 17845 4180

Mail: uk-hb@dfki.de

Media Contact

More Information:

http://www.dfki.deAll latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…