Researchers 3-D print first truly microfluidic 'lab on a chipl devices

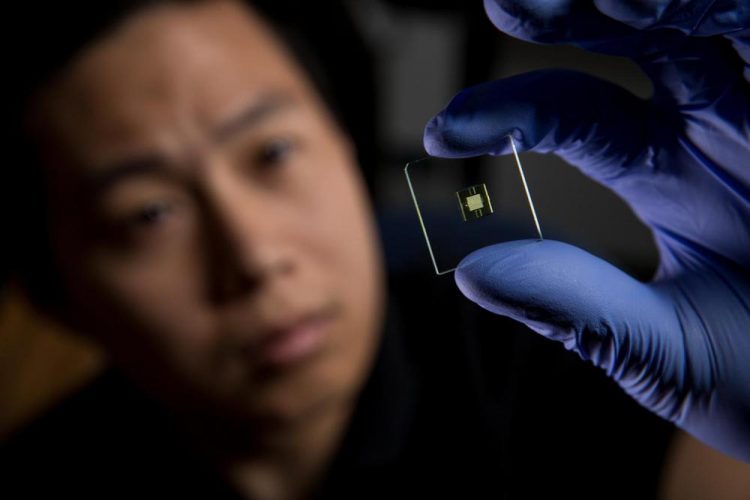

Hua Gong, a Ph.D. student at BYU, holds up a 3-D-printed microfluidic device. Credit: BYU Photo

Researchers at BYU are the first to 3D-print a viable microfluidic device small enough to be effective at a scale much less than 100 micrometers. Microfluidic devices are tiny chips that can sort out disease biomarkers, cells and other small structures in samples like blood by using microscopic channels incorporated into the devices.

The accomplishment, which is a major breakthrough toward mass-producing the medical diagnostic devices cheaply, is detailed online in academic journal Lab on a Chip. Researchers Greg Nordin, a BYU electrical engineering professor, and Adam Woolley, a BYU chemistry professor, say the key to their innovation was two-fold:

- Building their own 3D printer to print at a much higher resolution

- Using a new, specifically designed, low-cost, custom resin

“Others have 3D-printed fluidic channels, but they haven't been able to make them small enough for microfluidics,” Nordin said. “So we decided to make our own 3D printer and research a resin that could do it.”

Their work has produced labs on a chip with flow channel cross sections as small as 18 micrometers by 20 micrometers. Previous efforts to 3D-print microfluidic devices have failed to achieve success smaller than 100 micrometers. The researchers' 3D printer uses a 385 nm LED, which dramatically increases the available selection of UV absorbers for resin formulation compared to 3D printers with 405 nm LEDs.

Nordin said the advantages of 3D printing for microfluidic device fabrication are already well-known and that their method, digital light processing stereolithography (DLP-SLA), is an especially promising lower-cost approach. DLP-SLA uses a micromirror array chip, like those in most consumer projectors, to dynamically create the optical pattern for each layer during layer-by-layer printing of a device.

Researchers say they are laying the foundation for 3D printing to challenge the dominance of conventional methods — soft lithography and hot embossing — of microfluidic prototyping and development.

“We're deliberately trying to start a revolution in how microfluidic devices are fabricated,” Nordin said.

Woolley's research interests in microfluidics focus on using lab-on-a-chip devices to detect biomarkers related to preterm birth. To that end, he and Nordin just submitted a proposal to the National Institutes of Health to develop the approach in this paper for preterm birth prediction.

Woolley said the paper represents an improvement of a factor of 100 on the size of features that are now possible in 3D printed microfluidics. It also cuts down on time and hassle: the BYU-authored approach can create a device in 30 minutes' time and doesn't require the use of clean rooms — a special lab environment free from dust and other contaminants.

“It's not just a little step; it's a huge leap from one size regime to a previously inaccessible size regime for 3D printing,” Woolley said. “It opens up a lot of doors for making microfluidics more easily and inexpensively.”

Hua Gong is the BYU Ph.D. student who spearheaded the experimental work that made possible the 3D printing advances. Bryce Bickham, a BYU undergraduate, also played a key role in the research. Bryce, who just finished his freshman year, took on the challenge of digging through a 20-volume set of books detailing the spectra of possible resin materials. Nordin said Bryce found the perfect material thanks to his weeks-long effort in the BYU library. Hua then used this material to make a successful 3D printer resin.

Media Contact

All latest news from the category: Information Technology

Here you can find a summary of innovations in the fields of information and data processing and up-to-date developments on IT equipment and hardware.

This area covers topics such as IT services, IT architectures, IT management and telecommunications.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…