Escaping crisis with innovation: The University of Bayreuth founds a centre for 3D printing that is unique in Germany

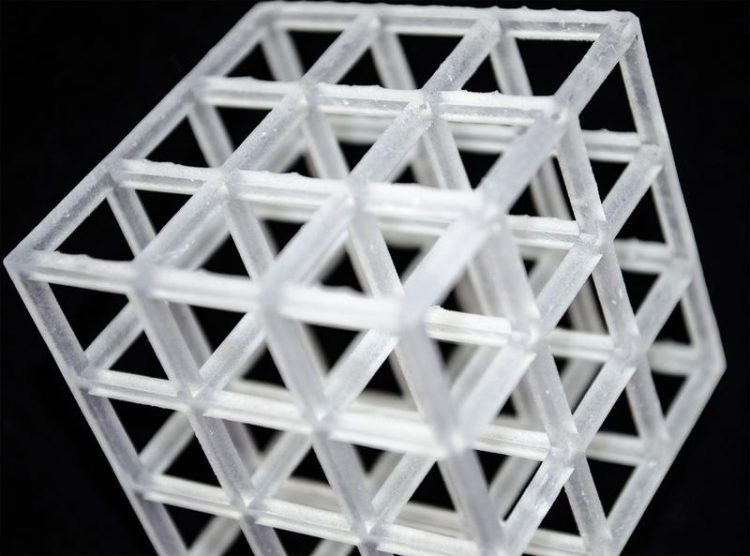

Additive manufacturing allows the precise production of three-dimensional structures in a single work process. Photo: LUP

“In the national and international research environment, additive manufacturing is usually viewed through the eyes of an engineer. But only if this future field is developed in an interdisciplinary and coherent way, can the unique and sustainable innovations of tomorrow come to fruition with and through additive manufacturing”, says Prof. Dr.-Ing. Frank Döpper, Chair of Manufacturing and Remanufacturing Technology at the University of Bayreuth.

The research centre Campus Additive.Innovations seeks to institute this approach as a matter of priority. Materials, technologies, and applications of additive production, as well as business models are to be investigated, developed, and optimised from many perspectives in an interdisciplinary way.

In so doing, the societal consequences of such technology, not just at a regional level but also around the world, will be taken into full account.

“Our many years of experience in cooperation with industrial partners, in particular with small and medium-sized companies, show one thing in particular. For the move to additive manufacturing to be profitable long term, it is essential to look at the entire value chain right from the outset – starting with customer-oriented product development and manufacturing processes, through to change management and strategic management,” says Christian Bay of the Manufacturing and Remanufacturing Technology research group.

Pooling and expanding scientific expertise

“The University of Bayreuth prides itself on linking fields of research and knowledge transfer that are strictly separated by subject and faculty boundaries elsewhere. This central idea has now also been incarnated by Campus Additive.Innovationen, which sees itself as an inter- and transdisciplinary think tank”, says Prof. Dr. Stefan Leible, President of the University of Bayreuth, describing the profile of the new research centre.

From natural and engineering sciences, to law and economics, all the way to sports and African studies, this is where the most diverse specialist competencies and technologies are combined and developed further. The main focus is on design, materials and processes, digitization, business models, and legal issues.

However, the interdisciplinary excellence which is growing on the campus of the University of Bayreuth as a consequence will provide pioneering impetus for innovation in research and development.

This systematic networking of technical and non-technical issues and competencies in the field of additive manufacturing is currently unique in Germany.

Increasing the competitiveness of companies

Especially companies from the regional environment are invited to see for themselves the potential and applications of additive manufacturing in the laboratories and pilot plants on the Bayreuth campus. At the same time, CA.I is developing offerings for school, vocational, and scientific education and training in consultation with the regional industry bodies and the Campus Academy of the University of Bayreuth.

“Additive manufacturing allows companies great freedom in the development of products and services. Moreover, it does not require the classic tools of industrial production. It is therefore to be expected that this technology will bring with it some disruptive effects.

It is precisely for this reason that the Campus Additive.Innovations research centre aims to enable the large and successful community of regional SMEs to make optimum use of the fascinating new opportunities at a very early stage, thus strengthening their own innovative power in the long term.

With its systematic networking of scientific, technical, and economic challenges, the research centre will be able to develop a significance that reaches far beyond our own region,” says Christian Bay.

Creating resilient value chains

The good teamwork between science and industry has also been evident during the coronavirus crisis. Recently, prototypes and application components for medical equipment were developed and additively manufactured at the University of Bayreuth, with the assistance of regional industrial partners.

“Beyond the current crisis, additive technologies in general have great potential to reduce the susceptibility of companies to crisis. They offer numerous possibilities to close gaps in value-added chains as they arise, ensuring customers are provided with important products, and thus to make companies more resistant to crisis situations”, claims Prof. Dr.-Ing. Frank Döpper.

Prof. Dr.-Ing. Frank Döpper

Chair of Manufacturing and Remanufacturing Technology

University of Bayreuth

Phone: +49 (0) 921 78516-100

E-Mail: frank.doepper@uni-bayreuth.de

Christian Bay

Assistant Lecturer in Manufacturing and Remanufacturing Technology

University of Bayreuth

Phone: +49 (0) 921 55-7309

E-Mail: christian.bay@uni-bayreuth.de

Media Contact

More Information:

http://www.uni-bayreuth.de/All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

Solving the riddle of the sphingolipids in coronary artery disease

Weill Cornell Medicine investigators have uncovered a way to unleash in blood vessels the protective effects of a type of fat-related molecule known as a sphingolipid, suggesting a promising new…

Rocks with the oldest evidence yet of Earth’s magnetic field

The 3.7 billion-year-old rocks may extend the magnetic field’s age by 200 million years. Geologists at MIT and Oxford University have uncovered ancient rocks in Greenland that bear the oldest…

Decisive breakthrough for battery production

Storing and utilising energy with innovative sulphur-based cathodes. HU research team develops foundations for sustainable battery technology Electric vehicles and portable electronic devices such as laptops and mobile phones are…