These flexible feet help robots walk faster

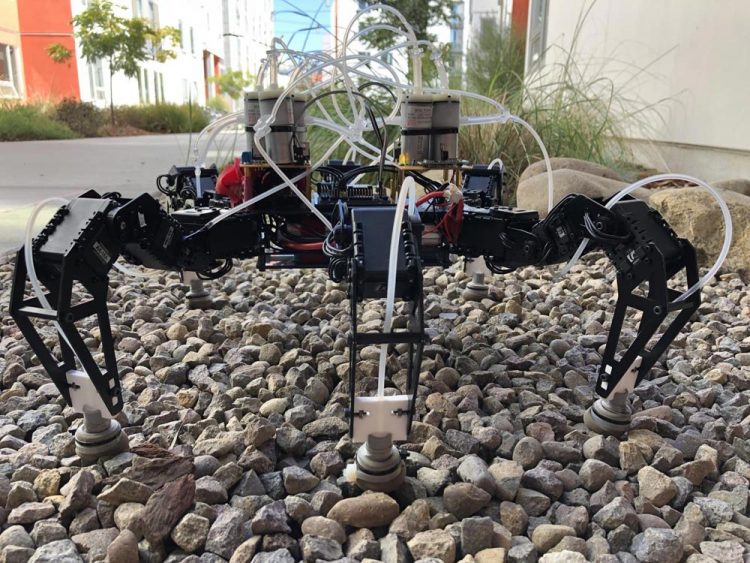

An off-the-shelf six-legged robot equipped with the feet designed by UC San Diego engineers can walk up to 40 percent faster than when not equipped with the feet. Credit: University of California San Diego

“Robots need to be able to walk fast and efficiently on natural, uneven terrain so they can go everywhere humans can go, but maybe shouldn't,” said Emily Lathrop, the paper's first author and a Ph.D. student at the Jacobs School of Engineering at UC San Diego.

The researchers will present their findings at the RoboSoft conference which takes place virtually May 15 to July 15, 2020.

“Usually, robots are only able to control motion at specific joints,” said Michael T. Tolley, a professor in the Department of Mechanical and Aerospace Engineering at UC San Diego and senior author of the paper.

“In this work, we showed that a robot that can control the stiffness, and hence the shape, of its feet outperforms traditional designs and is able to adapt to a wide variety of terrains.”

The feet are flexible spheres made from a latex membrane filled with coffee grounds. Structures inspired by nature? such as plant roots? and by man-made solutions? such as piles driven into the ground to stabilize slopes? are embedded in the coffee grounds.

The feet allow robots to walk faster and grip better because of a mechanism called granular jamming that allows granular media, in this case the coffee grounds, to go back and forth between behaving like a solid and behaving like a liquid.

When the feet hit the ground, they firm up, conforming to the ground underneath and providing solid footing. They then unjam and loosen up when transitioning between steps. The support structures help the flexible feet remain stiff while jammed.

It's the first time that such feet have been tested on uneven terrain, like gravel and wood chips.

The feet were installed on a commercially available hexapod robot. Researchers designed and built an on-board system that can generate negative pressure to control the jamming of the feet, as well as positive pressure to unjam the feet between each step.

As a result, the feet can be actively jammed, with a vacuum pump removing air from between the coffee grounds and stiffening the foot. But the feet also can be passively jammed, when the weight of the robot pushes the air out from between the coffee grounds inside, causing them to stiffen.

Researchers tested the robot walking on flat ground, wood chips and pebbles, with and without the feet. They found that passive jamming feet perform best on flat ground but active jamming feet do better on loose rocks. The feet also helped the robot's legs grip the ground better, increasing its speed. The improvements were particularly significant when the robot walked up sloped, uneven terrain.

“The natural world is filled with challenging grounds for walking robots—slippery, rocky, and squishy substrates all make walking complicated,” said Nick Gravish, a professor in the UC San Diego Department of Mechanical and Aerospace Engineering and study coauthor. “Feet that can adapt to these different types of ground can help robots improve mobility.”

In a companion paper co-authored by Tolley and Gravish with Ph.D. student Shivan Chopra as first author, researchers quantified exactly how much improvement each foot generated. For example, the foot reduced by 62 percent the depth of penetration in the sand on impact; and reduced by 98 percent the force required to pull the foot out when compared to a fully rigid foot.

Next steps include incorporating soft sensors on the bottom of the feet to allow an electronic control board to identify what kind of ground the robot is about to step on and whether the feet need to be jammed actively or passively.

Researchers will also keep working to improve design and control algorithms to make the feet more efficient.

###

Shear Strengthened Granular Jamming Feet for Improved Performance over Natural Terrain

Emily Lathrop, Nick Gravish and Michael T. Tolley, Department of Mechanical and Aerospace Engineering, UC San Diego Iman Adibnazari, Department of Electrical and Computer Engineering, UC San Diego

Video at https:/

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…