Sensor systems for Industry 4.0

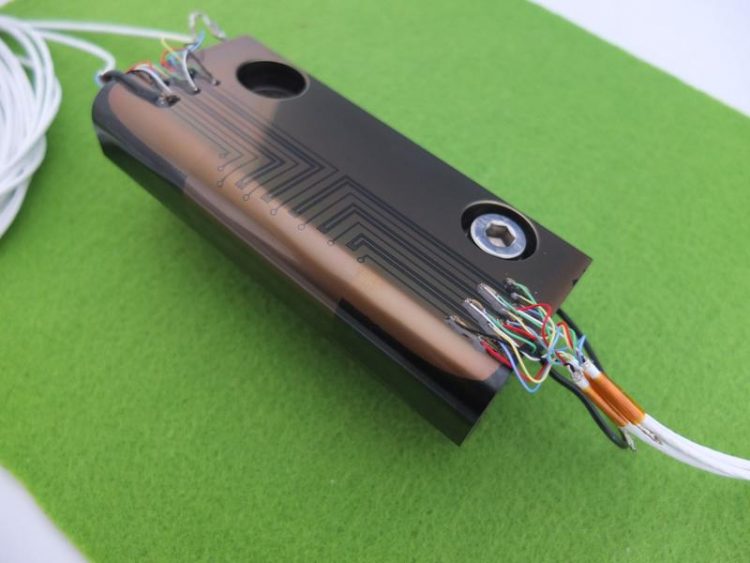

Strip metal drawing die with full thin film sensor system © Fraunhofer IST

In optimizing production processes it is very important to generate measurement data at locations where measuring systems can only be integrated with difficulty, such as, for example, in direct contact between workpiece and tool.

The Fraunhofer IST is developing thin film sensors with which manufacturing can be monitored in the main stress zones, directly on the tools. The new sensorized coating systems are multisensoric – in other words, they contain not only piezoresistive but also thermoresistive sensor structures embedded in the wear-protection layers.

It is thus possible for the first time to measure stresses and temperatures simultaneously and with spatial resolution. With these measurement results production processes can be optimized so that, for example, cracks and creasing during the deep-drawing of sheet metal can be minimized or plastic injection-molding processes can even be improved with respect to cycle times.

It is precisely in the age of Industry 4.0 that this further development of integrated sensor technology is gaining enormously in importance. The dominant topic in the production landscape of Europe, especially in Germany, is a qualitative, quantitative, flexible and at the same time resource-efficient production.

The basis for this development is a very good understanding of the production processes on the basis of human experience and measurement results. “This is where we start with our thin-film sensors in supplying the important data needed for simulations”, says Dr. Saskia Biehl, head of the “Micro and sensor technology” group at the Fraunhofer IST.

At the Fraunhofer Adaptronics Alliance joint booth (C22) in Hall 2 the Fraunhofer IST presents the new multisensoric coating systems.

About the project

The results we have described were obtained within the SensoFut project (Sensorized Future – Sensing of temperature and pressure in harsh environments), on which the Fraunhofer IST worked together with the Fraunhofer Institute for Machine Tools and Forming Technology IWU and Sirris, the Belgian research association. SensoFut is funded in the 13th Cornet Call (Collective Research Networking) by the Federal Ministry of Economics and Technology (BMWI) and the German Federation of Industrial Research Associations (AiF) and runs until June 30, 2015.

Weitere Informationen:

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…