Microchip industry strives to perfect its timing

Time is money, especially to the semiconductor industry. Electronics manufacturers use extremely sophisticated equipment to churn out the latest microchips, but they have a timing problem. It’s very difficult to get all the fabrication tools in a manufacturing line to agree on the time. Components within a single tool can disagree on the time by as much as two minutes, because of a lack of synchronization.

According to a new report by the National Institute of Standards and Technology (NIST) and International SEMATECH,* the timing deficiencies will become important as device dimensions and tolerances continue to shrink. In particular, timing becomes critical as firms advance e-manufacturing concepts such as real-time automation and intelligent control.

Tools can be synchronized to about 100 millisecond (ms) accuracies today, but with significant variations. The problems are myriad, according to the report. For instance, subsystems made by suppliers may lack the interfaces needed to synchronize their clocks with host clocks made by original equipment manufacturers. Quality control software that relies on time stamps to diagnose processing errors may overload the computing resources of fabrication systems, therefore degrading the time stamp accuracy. There also is pressure to move forward: Methods are available to reach 1 ms accuracy in the near future, but sub-millisecond accuracies will be required eventually.

To help achieve that level of precision, NIST is leveraging its timekeeping expertise to support the industry’s development of time synchronization standards in collaboration with International SEMATECH’s e-Manufacturing initiatives. A next-generation time synchronization protocol under development by the Institute of Electrical and Electronics Engineers should improve the outlook, and NIST has developed educational presentations and white papers to summarize the key issues and potential solutions. In addition, NIST plans to facilitate future standards development, possibly under a new Time Synchronization Working Group, chartered by Semiconductor Equipment Materials International.

Media Contact

More Information:

http://www.nist.govAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Boron deficiency: oilseed rape reacts as with infection and pest infestation

Genetic mechanisms uncovered… Boron deficiency has a devastating effect on oilseed rape and related plants. However, little is known about the underlying genetic mechanisms. A study shows that the response…

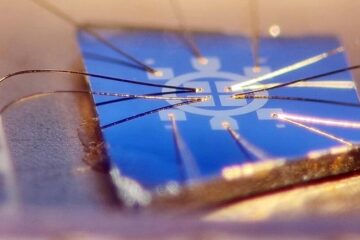

Quantum Precision: A New Kind of Resistor

Researchers at the University of Würzburg have developed a method that can improve the performance of quantum resistance standards. It´s based on a quantum phenomenon called Quantum Anomalous Hall effect….

Security vulnerability in browser interface

… allows computer access via graphics card. Researchers at Graz University of Technology were successful with three different side-channel attacks on graphics cards via the WebGPU browser interface. The attacks…