Reliability of TPedge PV Modules Successfully Tested

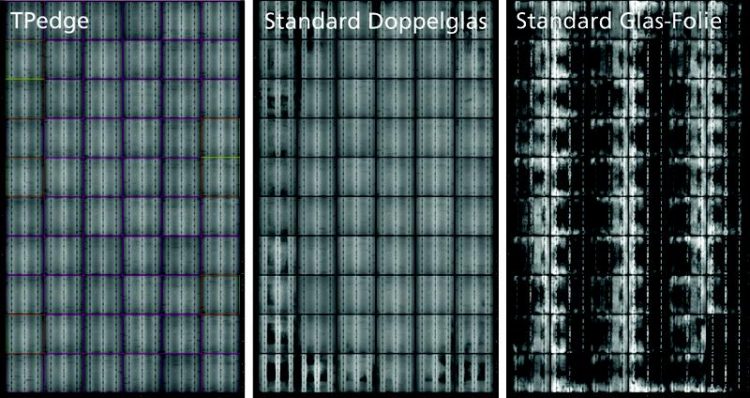

Electroluminescence images of the tested modules after 4000 hours of humidity-heat tests (85 °C, 85% r.H.); TPedge module (left), glass-glass-laminate (middle), glass-foil-laminate (right). ©Fraunhofer ISE

TPedge modules are edge-sealed, double-glass PV modules, similar in construction to insulating glass windows. The solar cells are fixed in the gas-filled space between the two glass panes with special adhesive pins. The TPedge module forgoes the conventional encapsulation foils as well as the traditional module frame.

This not only saves material costs but also avoids the time-consuming lamination process. In the project “TPedge – Development of a Technology for Edge-Sealed Solar PV Modules,” Fraunhofer ISE and the company Bystronic glass together developed processes for the industrial production of novel solar module concepts. “We have successfully transferred the lab prototype to an industrial-scale module (with 60 solar cells),” says a pleased Max Mittag, project head at Fraunhofer ISE.

At the PV Module-TEC (Module Technology Center) at Fraunhofer ISE, the researchers put automated production systems into operation with which they were able to produce numerous prototypes of TPedge PV modules with different setups. As a next step, the industrial production processes were developed further and optimized.

By substituting the 3 mm thick glass with glass that is only 2 mm thick, the weight of the TPedge modules could be reduced by 30 percent. The module prototypes jointly produced with Bystronic glass underwent many tests based on the standards IEC 61730 and 61215, and the results confirmed the high reliability and technical maturity of the TPedge module concept.

Many different design setups were tested, using the conventional glass-foil-laminate and glass-glass-laminate modules as a reference. As part of the procedure, the PV modules were tested for their resistance to hail and distributed loads.

Aging Stability

In the humidity-heat test, various TPedge modules containing different types of commercial solar cells were subjected to a relative humidity of 85 percent at a temperature of 85 °C for over 4000 hours. After the test, the module power showed no change compared to the initial values measured before exposure. Conventional module concepts, however, with glass-foil-laminate and glass-glass-laminate demonstrated, in part, large degradation effects after undergoing the same test. The TPedge modules also successfully passed the thermal cycle durability test. Fraunhofer ISE’s TestLab PV Modules verified the durability of the TPedge modules by exposing them to 400 temperature cycles (-40 °C … + 85 °C) in the testing process.

Mechanical Durability

Using commercially available mounting systems, durability tests for mechanical loads and hail were carried out at Fraunhofer ISE. The tested modules successfully passed the tests in which pressure loads up to 5400 Pa were applied to the modules in different mounting configurations. Although the tests were repeatedly carried out, no changes in the module power were detected. The TPedge concept was also tested for its resistance to hail. Even the modules with the thinner 2 mm thick glass passed the tests successfully. In the procedure, large hail stones of 25 mm diameter were also aimed at especially critical parts of the module, for example, the glass edges. The modules passed the hail tests without being damaged and could be used further in the following tests.

Cost Savings

With a special model developed at Fraunhofer ISE to determine the cost of ownership according to the SEMI standard, a highly precise cell-to-module power analysis (CTM), and measurements from the CalLab PV Modules, the specific module costs (€/Wp) for TPedge and relevant competitive module technologies were calculated. “The results show that the specific module costs of the TPedge concept are approximately 2 percent less than the conventional glass-foil-laminate concept,” says Mittag. “The cost reduction is mostly due to lower material costs. Material costs are crucial since they are responsible for ca. 90 percent of the total module production costs, including cells.” The TPedge concept also lowers material costs compared to the glass-glass-laminate concept.

The project “TPedge” started at the beginning of 2013 and was funded by the German Federal Ministry for Economic Affairs and Energy (BMWi). Fraunhofer ISE and its project partner Bystronic glass developed the TPedge module technology and the possibilities for industrial production followed. Fraunhofer ISE has installed 70 TPedge modules on the façade of one of its lab buildings; these have been operating in a field test for three years now. Further research explores promising approaches to increase the module power and addresses the particular suitability of this technology for building-integrated photovoltaics. An industrial implementation of this technology is a future aim and partners are being sought.

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…