Performance boost for microchips

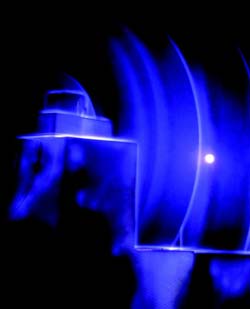

EUV Technology for the production of the next chip generation. Picture source: Fraunhofer-Institute for Laser Technology ILT, Aachen, Germany.<br>

Flat computers, powerful cell phones and tablets – the integrated circuits, our computers‘ power centers, are becoming increasingly smaller and more complex.

The microchips in today‘s computers already contain some two billion transistors. To get the chip density right, the structures are exposed onto the chips by means of lithography. To be able to meet future requirements, the semi-conductor industry is planning to convert the exposure using a wavelength of 193 nm to a wavelength of just 13.5 nm. This can be achieved only with completely new radiation sources.

The favorite of the Next-Generation lithography is EUV – light with wavelengths in the extreme ultraviolet range. Dr. Klaus Bergmann, Dr. Stefan Braun and Dr. Torsten Feigl from the Fraunhofer Institutes for Laser Technology ILT Aachen, for Material and Beam Technology IWS Dresden and for Applied Optics and Precision Engineering IOF Jena, have developed, with their teams, key elements for EUV lithography: light sources (ILT), collector optics (IOF) and illumination and projection optics (IWS). They will receive a 2012 Joseph-von- Fraunhofer prize for their achievements in this strategic partnership.

Generating EUV radiation

The efficiency of the light source is key to the industrial use of EUV. The team around Klaus Bergmann at ILT developed the first prototypes of the EUV source as early as 2006. There is now a beta version that is already being used to expose chips in industrial applications. “The concept is based on the rapid, pulsed discharge of electrically stored energy. In the process, a small amount of tin is vaporized using a laser and excited with a high current to an emission at 13.5 nm – many thousands of times per second”, explains Bergmann.

World‘s largest collector mirror for EUV lithography

The quality of the collector mirror is crucial to the radiation hitting the exposure mask in exactly the right place. The coating guarantees that the losses remain low and that the quality of the focused EUV radiation is high. “The challenge we faced was to develop and apply a multilayer coating system that combined high EUV reflectance with high thermal and radiation stability onto the strongly curved collector surface”, said Torsten Feigl from IOF. The result is the world‘s largest multi-layer coated EUV mirror with a diameter of more than 660 millimeters.

Coating for optimized reflection on mirrors and lenses

Once the radiation passed the mask, it is exposed onto the chips via further projection mirrors. Stefan Braun and his team at IWS have devised the optimum reflection layer for these components. Magnetron sputtering ensures maximum layer accuracy, without additional polishing processes or in-situ thickness control being required. One machine type for large area precision coating is already in industrial use. Germany is the pioneer of EUV technology. Three institutes have established themselves with their research work as key partners for the supplier industry both in and outside Europe. The new lithography technology is expected to start industrial production in 2015.

Joseph-von-Fraunhofer prize – research for practical applications

Since 1978, Fraunhofer-Gesellschaft has awarded the annual prizes for outstanding scientific achievements of its employees that resolve application-related problems. To date, more than 200 researchers have won this prize. This year, four prizes worth 20,000 euro each will be awarded. The prize winners will also receive a silver pin with the facial profile of the patron saint as it appears in the logo of articles 2 to 5.

Contacts at the Fraunhofer ILT

If you have any questions regarding this topic, please feel free to contact our experts:

Dr. Klaus Bergmann

Group Manager EUV Technology

Phone +49 241 8906-302

klaus.bergmann@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen

Phone +49 241 8906-0

Fax +49 241 8906-121

Media Contact

More Information:

http://www.ilt.fraunhofer.deAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…