Microwave-based test method can help keep 3-D chip designers' eyes open

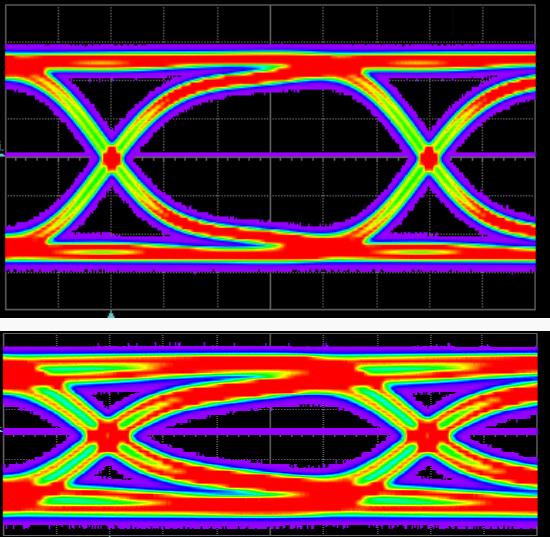

These 'eye' diagrams reveal how much noise is present in a digital signal. As the signal grows noisier, its characteristic shape grows distorted, shrinking the center so it resembles an eye closing. NIST's new 3-D chip-testing method passes microwaves through chip material, allowing researchers to quickly detect flaws that would create noise and make the diagram change from the open-eyed clarity of the top image to the squintier distortion on the bottom. Credit: Y. Obeng and N. Hanacek/NIST

The approach overcomes the limitation of conventional chip-testing methods on the so-called 3-D chips, which include many thin horizontal “floors” connected to one another by vertical pathways called through-substrate vias, or TSVs. These TSVs are essential to the operation of 3-D chips, which have become commercially viable only in the past few years after decades of sustained development effort by the industry.

With NIST's new testing method, chip designers may have a better way to minimize the effects of “electromigration,” a perennial cause of chip failure rooted in the wear and tear that relentless streams of flowing electrons inflict upon the fragile circuitry that carries them.

The NIST approach could give designers a quicker way to explore the performance of chip materials in advance, thereby providing more, and almost real-time, insight into what materials will best serve in a 3-D chip.

“Our work shows it may be possible to spot microscopic failures faster,” said NIST's Yaw Obeng, research chemist and the leader of the Metrology for Emerging Integrated Systems project. “Instead of waiting for months, we can see in days or hours when it's going to happen. You can run our tests during the material selection phase to see how processing will affect the end product. If you can't see it, you might make the wrong decision.”

If a 3-D chip were a high-rise building, TSVs would be its elevators. They help 3-D chips do three essential things: Speed up, shrink down and cool off. By allowing elements on different floors to communicate with each other, signals no longer need to travel all the way across a comparatively sprawling 2-D chip, meaning calculations go faster and electrons heat up far less conducting material as they move.

Along with these advantages, TSVs also carry one drawback: Their reliability is hard to test with the conventional method, which involves passing direct current through the conductor and waiting for its resistance to change. It is very time-consuming, requiring weeks or even months to show results. The chip industry needs a new metrology approach that is quick and realistic, and that would reveal the impact on the high-speed signal that actually runs through the conductors.

The new NIST testing method sends microwaves through the material and measures changes in both the amount and quality of the signal. Their testing setup, which simulates real-world conditions, repeatedly heats and cools the material, causing it to develop flaws, and over time, the microwave signal decreases in strength and decays from a clean, square-shaped wave to one that is noticeably distorted.

Using microwaves brings multiple benefits. Perhaps chief among them is how rapidly the method provides information about a device's reliability, in the actual device of interest, long before it actually fails–a possibility unavailable with the resistance-based approach.

“Before failure comes what we call a 'quiescent period' when the beginnings of defects are blowing around through the material, like seeds in the wind,” Obeng said. “The microwaves show this process happening. If you just watch the material with resistance, you don't see this, it's either alive or dead.”

Microwaves could reveal information about defects as quickly as three days after testing begins, while conventional tests can take months.

Obeng estimates this method could be fully implemented by industry within a few years, and could provide valuable insights.

“This approach would give materials designers insight into what materials to use in chips and how to build them,” he said. “Making the right decisions can result in an end product that's more stable and reliable. This will give them more information to make those decisions.”

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…