Microhotplates for a smart gas sensor

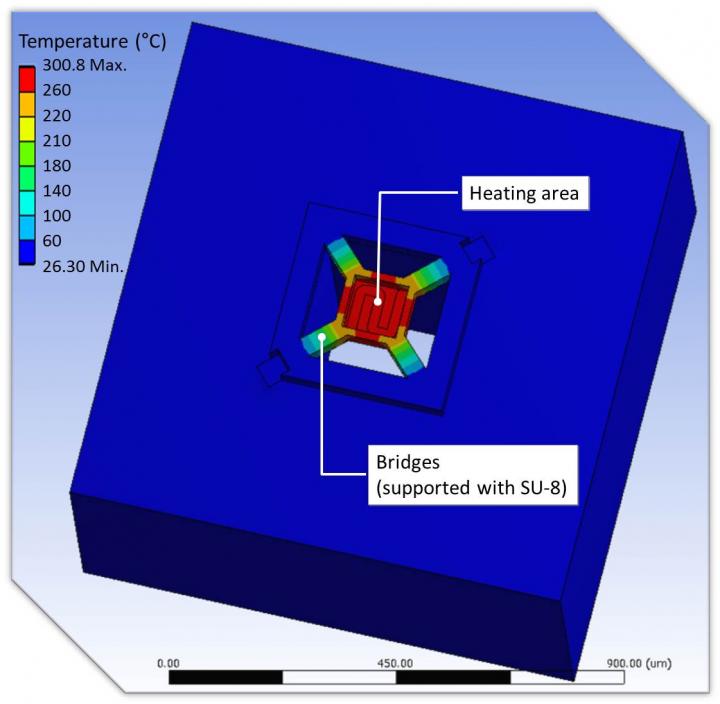

This is a simulation result of the temperature distribution in the proposed micro-hotplate. COPYRIGHT (C) TOYOHASHI UNIVERSITY OF TECHNOLOGY. ALL RIGHTS RESERVED.

Gas sensors used for leakage alerts and air quality monitoring are essential in our daily lives. Towards a ubiquitous society, smart gas sensors, which perform signal processing and communication besides sensing, have attracted much attention. In addition, integrating these functions into a single chip leads to low-cost and miniature smart gas-sensing systems.

Semiconductor gas sensors, which are the most widely used gas sensors, require a sensor material to be heated to several hundreds of degree Celsius. Therefore, in order to integrate these gas sensors with electronic circuits, a micro-hotplate (MHP), which is a MEMS-based heating structure, is required to thermally isolate the sensor and the circuits. The MHP is generally mechanically unstable, and there exists a tradeoff between the mechanical stability and thermal isolation property.

Recently, a research team at the Department of Electrical and Electronic Information Engineering at Toyohashi University of Technology proposed the employment of SU-8 as a supporting material for the MHP, in order to improve the mechanical stability, while ensuring the thermal isolation property. Furthermore, SU-8 is a polymer material that is widely used for microelectromechanical systems (MEMS) and has good mechanical stability and low thermal conductivity. The researchers fabricated the MHP and investigated its heating characteristics.

The first author Assistant Professor, Tatsuya Iwata, said that “By using a thick polymer film, it is possible to realize both the mechanical stability and high thermal isolation property. Furthermore, although we have to evaluate the mechanical stability, this device is promising for smart gas sensors.”

“Mechanical stability is one of the major concerns for fabricating an MHP. Using a polymer material for such microhotplates seems to be an eccentric approach, but surprisingly, it went well. Moreover, this device will boost our study to develop multimodal sensors, which are multifunctional integrated sensors including gas sensors,” said Professor Kazuaki Sawada.

The fabricated MHP consists of a heating membrane with an area of 140 μm × 140 μm, and a 33-μm-thick SU-8 layer deposited on its bridges. The simulation confirmed that the MHP displayed good thermal isolation properties (Fig. 1). The MHP temperature was found to reach 550 °C at 5V. Moreover, the power consumption of the MHP approximately corresponded to 13.9 mW for heating to 300 °C, which is comparable with the power consumption reported in the previous studies. Furthermore, a stable operation under a constant voltage was observed for 100 min.

Owing to the thick SU-8 layer, the MHP does not need the strict control of the stress that occurs inside the membrane during the fabrication process. This feature, together with the good thermal isolation property, enables the flexible layout design of the chip, and therefore, the MHP is beneficial to a miniature smart gas sensor chip. The researchers will advance their study to realize such smart gas sensors.

###

This research results were reported in the Journal of Micromechanics and Microengineering, on January 11, 2017.

Funding agency: Japan Society for Promotion of Science, Grant-in-Aid for Young Scientists (B), Grant Number 15K18049

Reference:

T. Iwata, W. P. C. Soo, K. Matsuda, K. Takahashi, M. Ishida, and K. Sawada (2017), Design, fabrication, and characterization of bridge-type microhotplates with an SU-8 supporting layer for a smart gas sensing system, J. Micromechanics Microengineering, 27(2), 24003.

https:/

Further information

Toyohashi University of Technology

1-1 Hibarigaoka, Tempaku

Toyohashi, Aichi Prefecture 441-8580, JAPAN

Inquiries: Committee for Public Relations

E-mail: press@office.tut.ac.jp

Toyohashi University of Technology, which was founded in 1976 as a National University of Japan, is a leading research institute in the fields of mechanical engineering, advanced electronics, information sciences, life sciences, and architecture.

Website: http://www.

Media Contact

Ryoji Inada

press@office.tut.ac.jp

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…