Combining infrared radiation and air management to reduce energy use

Infradry systems make printing and coating applications significantly more efficient. Copyright Heraeus Noblelight 2019

Drying coatings and inks is an energy-intensive process, which is reason enough to put conventional dryers to the test.

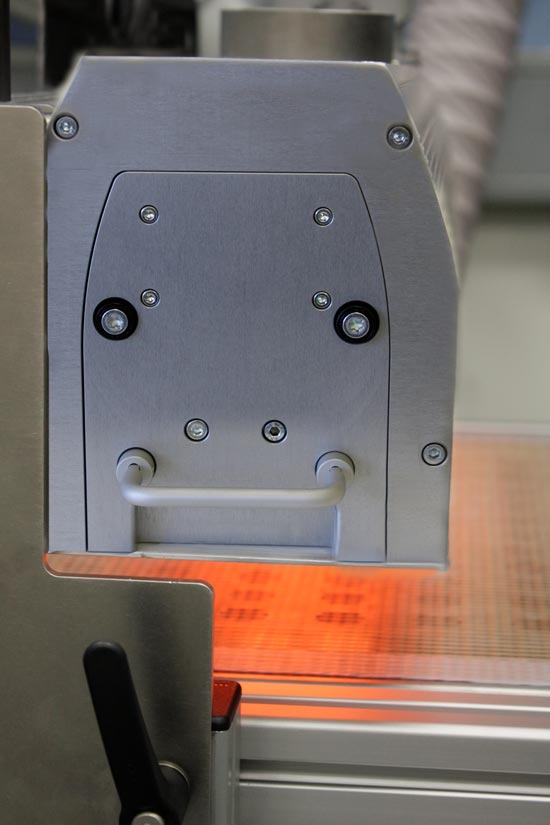

Infradry modules combine intensive IR radiation with a controlled air supply and exhaust system to ensure effective drying.

This was accomplished with the help of computational fluid dynamics (CFD) to coordinate radiation and air extraction via computer simulation before the system was built.

Initial tests with customer materials confirmed the simulation.The drying speed was up to 20 percent faster than with conventional dryers.

Highly efficient drying

The air management system has been designed to absorb and then remove the moisture that is driven out of the coating by the IR emitters. This accelerates drying by preventing the atmosphere inside the process area from becoming oversaturated.

With a power density that is customized to the application and highly polished reflectors that concentrate the infrared radiation on the substrate surface, the new Infradry systems provide very efficient drying.

Their modular construction makes them easily scalable for any working width, and they can be configured with a variety of interfaces. Infinitely variable power ensures exact control of drying.

Powerful twin-tube infrared emitters

There are currently two types of Infradry systems:The Infradry Compact has a very small footprint, and is easily expandable. The Infradry Combi is suitable for larger facilities and is the first drying system in the world to extract the air between the emitters within the infrared emitter field. Unlike conventional dryers, the moisture is extracted directly from the process area, making infrared drying more thorough, as a result.

High-performance twin-tube IR emitters provide the heat for drying inks and dyes. Depending on the application, shortwave or mediumwave emitters can be selected. Shortwave emitters produce very high temperatures very quickly, while mediumwave emitters are considered the most efficient method to dry inks and coatings gently to protect the paper.

Heraeus Noblelight offers the whole range of infrared radiation—from near infrared (NIR) to mediumwave carbon infrared (CIR), conducts trials with the materials, and provides guidance in selecting the optimal emitter for every process.

A globally leading technology group, Heraeus is headquartered in Hanau, Germany. Founded in 1851, it is a family-owned portfolio company which traces its roots back to a pharmacy opened by the family in 1660. Today, Heraeus combines businesses in the environmental, energy, electronics, health, mobility and industrial applications sectors.

In the 2017 financial year, Heraeus generated revenues of €21.8 billion. With approximately 13.000 employees in 40 countries, the FORTUNE Global 500-listed company holds a leading position in its global markets. Heraeus is one of the top 10 family-owned companies in Germany.

With technical expertise, a commitment to excellence, a focus on innovation and entrepreneurial leadership, we are constantly striving to improve our performance. We create high-quality solutions for our clients and strengthen their long-term competitiveness by combining unique material expertise with leadership in technology.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France and China is one of the technology- and market-leaders in the production of specialty light sources and systems. In 2017, Heraeus Noblelight employed 762 people worldwide. The organization develops, manufactures and markets infrared and ultraviolet emitters, systems and solutions for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical measurement techniques.

Further information:

Technical: Heraeus Noblelight GmbH

Reinhard-Heraeus-Ring 7

D-63801 Kleinostheim

Tel +49 6181/35-8545, Fax +49 6181/35-16 8545

E-Mail hng-infrared@heraeus.com

Press: Dr. Marie-Luise Bopp

Heraeus Noblelight GmbH,

Tel +49 6181/35-8547, Fax +49 6181/35-16 8547

E-Mail marie-luise.bopp@heraeus.com

Media Contact

All latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…