Job autonomy, trust in leadership keys to improvement initiatives

According to a soon-to-be-published study by Gopesh Anand and Dilip Chhajed, professors of business administration at Illinois, a flexible work environment plays a significant role in increasing employee commitment to continuous improvement initiatives.

“Continuous improvement initiatives are typically bundled with employee empowerment techniques,” Anand said. “We always hear, ‘If you empower employees, they will take care of the improvements.’ But what happens repeatedly is that this employee empowerment is management-driven, and it does not work.”

“It’s a paradox – employee empowerment being forced upon employees by management,” said Chhajed, who also is the director of the technology management program in the College of Business. “What usually ends up happening is that employees feel they are being forced into doing something that they may not even see as being very useful.”

The research, co-written with Luis Delfin, a former graduate student, advances three arguments on how employees’ commitment to continuous improvement in the workplace can be enhanced:

The day-to-day work environment needs to be perceived by employees as autonomous.

As continuous improvement involves making changes to the very practices that frontline employees use in their day-to-day work, trust in leadership is critical.

A higher degree of trust in leadership further leads to proactive behaviors by frontline employees, encouraging them to use the autonomy in their day-to-day jobs to seek out and make systematic improvements to work practices.

The researchers tested their hypotheses on data collected from individual employees working for Christie Clinic, an outpatient health care organization based in Champaign, Ill., that has actively engaged in continuous improvement based on lean management principles over the last six years.

While previous research on continuous improvement initiatives focuses on constituent elements such as rewards, leadership and training opportunities that are explicitly tied to generating employee participation, this study focuses on the association of commitment to continuous improvement with the context of every employee’s day-to-day work.

“Many times, employees end up working on continuous improvement projects simply because the CEO is telling them to participate in the initiative,” Anand said. “But they aren’t really sold on this idea of making an effort to improve their workplace and work practices.”

“Workers need to have a sense of control over their work environment,” Delfin said. “They need to be able to decide how and what to do in their day-to-day work. And that’s actually what motivates them to improve. Their buy-in becomes even stronger when leadership provides them the support to do this.”

Employees shouldn’t end up thinking of improvement initiatives as extra work as such an attitude ultimately leads to “change fatigue,” the researchers say.

“Employees can’t think of it as, ‘This is something being brought down upon us by upper management,’ ” Anand said. “If they do, it becomes extra work that they’re not compensated for.”

“The big one for employees is, ‘What’s in it for me?’ ” Chhajed said. “Management is trying to make things more efficient, so what does that mean for my job, my work hours? That’s why employees need to trust that management is looking out for their best interests. If they don’t have that trust, then even autonomy is not going to help as much. Trust is huge, because you don’t want the perception that management is coercing employees to do this.”

Management shouldn’t be the sole driver of change in an organization, and the process for implementing a continuous improvement initiative likewise shouldn’t be a top-down mandate.

“There should be some top-down direction in terms of where the initiative should go and what are we in business for,” Anand said. “But there needs to be balance between the top-down goals and the bottom-up improvements.

“It’s like building a bridge from both sides,” Delfin said. “Upper management usually has the vision, but at the same time they’re not the experts on how things get done on the ground. So you need to have frontline employees who have some freedom because you are trying to get all of this to meet in the middle. That means that the leaders in management need to act more like coaches, and less like dictators. You need a cooperative environment where leaders are guiding and coaching, and employees are participating.”

Although their empirical context is a health care organization, the researchers say that their results are applicable to most organizations that are deploying continuous improvement initiatives.

“The problems that we look at in this paper are prevalent across industries,” Chhajed said.

“If you talk to people in any industry who are deploying continuous improvement initiatives, they are facing these issues,” Anand said. “That’s why you see new iterations of these types of initiatives over and over, because organizations often fail at sustaining them over long periods of time.”

The paper will appear in the journal Operations Management Research.

Media Contact

More Information:

http://www.illinois.eduAll latest news from the category: Business and Finance

This area provides up-to-date and interesting developments from the world of business, economics and finance.

A wealth of information is available on topics ranging from stock markets, consumer climate, labor market policies, bond markets, foreign trade and interest rate trends to stock exchange news and economic forecasts.

Newest articles

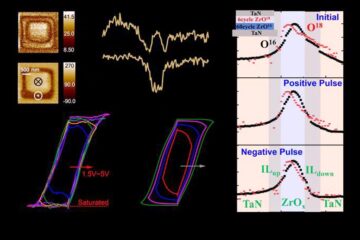

Evidence for reversible oxygen ion movement during electrical pulsing

…enabler of the emerging ferroelectricity in binary oxides. In a recent study published in Materials Futures, researchers have uncovered a pivotal mechanism driving the emergence of ferroelectricity in binary oxides….

Next-generation treatments hitch a ride into cancer cells

Researchers from Osaka University discover that opening a channel into cancer cells helps antisense oligonucleotide drugs reach their targets. Antisense oligonucleotides (ASOs) are next-generation drugs that can treat disease by…

Boron deficiency: oilseed rape reacts as with infection and pest infestation

Genetic mechanisms uncovered… Boron deficiency has a devastating effect on oilseed rape and related plants. However, little is known about the underlying genetic mechanisms. A study shows that the response…