Siemens to supply bar rolling line for minimill in India

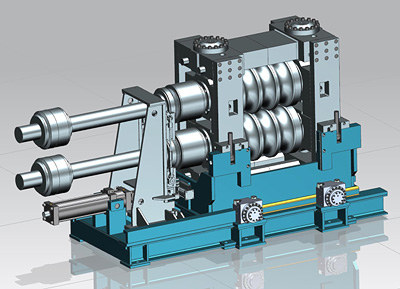

CGA sizing stand from Siemens

SLR Metaliks Ltd., an Indian pig-iron producer, has awarded Siemens Metals Technologies an order to supply a state-of-the-art bar rolling mill for its new steel plant near Hospet. The rolling mill will be designed for an annual production of 320,000 metric tons of rebars and special bar quality (SBQ) grades, primarily for the automotive industry. Bars with smaller diameters will be rolled in multi-slit mode. The new steel plant in Hospet is a value-addition project within the expansion plan of SLR Metaliks Ltd. The bars will be produced to serve both national and international markets. The plant is scheduled to be brought into operation in the first half of 2016.

Siemens will supply the complete process equipment for the new bar rolling mill, including the billet infeed with a hot charging option, the descaling, and the handling of the finished bars. The actual rolling line will consist of a roughing mill and an intermediate mill, each with six Red Ring stands in an HV arrangement, and a finishing mill with six Red Ring stands in an HVC arrangement. This will be followed downstream by a three-stand sizing mill with CGA stands in an HVH arrangement. An inline system will be used for thermo-mechanically rolling the SBQ bars, as well as for quenching and tempering the rebars. The quality of the rolled bars will be controlled by measuring inline the dimensions and profiles with non-contact, laser-based Orbis measuring systems while the mill is running.

A hot dividing and crop shear will be installed between the rolling mill and the cooling bed. Downstream of the cooling bed, another dividing shear will cut the rolled bars to length. This will be followed by automatic bundling, wire-tying and weighing machines. The maximum bundle weight will be five metric tons. The scope of delivery also includes the rolling guides and the fluid systems. Siemens will also supply the low-voltage transformers, motors, drives, mechatronic packages and measuring instruments, as well as the basic L1 automation, including the operator consoles, and the HMI system. Siemens is responsible for the design of the equipment supplied, the entire process planning of the bar rolling mill, and for the customer training. It will also assist the customer with the construction, start-up and commissioning of the plant.

The bar rolling mill will be fed with six-meter billets of carbon and quality steels with a square cross-section of 130 x 130 or 160 x 160 millimeters, and process them to produce rebars with diameters ranging from 8 to 32 millimeters, and SBQ rounds with diameters from 16 to 63 millimeters. The operators will also have the option of producing bars with square and hexagonal cross-sections.

The Metals Technologies Business Unit (Linz, Austria) is one of the world's leading life-cycle partners for the metallurgical industry. The Business Unit offers a comprehensive technology, modernization, product and service portfolio as well as integrated automation and environmental solutions covering the entire life cycle of plants.

For further information on solutions for steelworks, rolling mills and processing lines, please see www.siemens.com/metals

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years. The company is active in more than 200 countries, focusing on the areas of electrification, automation and digitalization. One of the world's largest producers of energy-efficient, resource-saving technologies, Siemens is No. 1 in offshore wind turbine construction, a leading supplier of combined cycle turbines for power generation, a leading provider of power transmission solutions and a pioneer in infrastructure solutions and automation and software solutions for industry. The company is also a leading supplier of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In fiscal 2013, which ended on September 30, 2013, revenue from continuing operations totaled €75.9 billion and income from continuing operations €4.2 billion. At the end of September 2013, Siemens had around 362,000 employees worldwide on the basis of continuing operations. Further information is available on the Internet at www.siemens.com.

Reference Number: PR2014100029PDEN

Contact

Mr. Rainer Schulze

Process Industries and Drives Division

Siemens AG

Turmstr. 44

4031 Linz

Austria

Tel: +49 (9131) 7-26616

All latest news from the category: Corporate News

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…