Screening for High Protein Secretion

Industrial production of proteins using yeast is typically performed using fed-batch or continuous culture. The search for improved production strains is often carried out using random mutagenesis and screening using high-throughput techniques at microtiter scale.

However, there is a great difference in the physiological state of the cells between batch and fed-batch or continuous culture. Thus, results obtained under batch conditions are not always accurate indications of the performance during industrial production.

The following application note describes the screening process for high protein secretion in mutant strains of Saccharomyces cerevisiae, developed at Novo Nordisk in Denmark(*). For the strains expressing insulin analogue precursors, they used a DASGIP Parallel Bioreactor System featuring integrated temperature and agitation control for eight 200 mL vessels in the DASGIP Bioblock. Thus, this system offered a scale large enough for small preparations of protein while requiring less than 2 m² bench top space.

The Project

The aim of the project was to obtain a significant reduction in the number of bench-top fermentations used for early strain evaluation. They established a scale-up protocol in four steps that monitored protein production. In each step, the number of strains decreased, and the controlled parameters increased.

1. Batch culture: The batch culture was performed in shake-flasks, with controlled temperature and buffered medium (pH decrease 1 unit during run) and an Applikon Micro-24 Bioreactor: 24 x 5 mL, controlling the temperature, pH, and pO2. Primary screening in batch culture, normalised precursor concentration in 5mL batch culture, 4% glucose, 72h sample. 115 spore clones of the same hybrid were tested The 16 clones marked * were included in the secondary screening.

2. Fed-batch culture: The fed-batch-phase was carried out over 48 h in a DASGIP Bioblock controlling temperature, pH, pO2, biomass, insulin precursor and metabolites to verify respiratory growth.

3. Continuous culture: Batch-end detection was based on the decrease in CO2 at glucose depletion, in order to synchronize the cultures. Temperature, pH, pO2, biomass, insulin precursor as well as metabolites were controlled.

(*)Authors of the poster “Screening for High Protein Secretion in Mutant Strains of Saccharomyces cerevisiae” were Eva Akke Palmqvist, Peter Becker, Per Nørgaard and Inga Sig Nielsen Nørby. Screening for High Protein Secretion Optimization of Fermentation for Mutant Strains of S. cerevisiae

4. Productostat: To determine the full potential of a strain, a determination was done in a productostat. After 48 h continuous culture the dilution-rate was automatically increased until the ethanol concentration in the tank reaches a set-point value.

Results

Screening in batch culture only gave very preliminary information about the strain behaviour and the potential of the strain in fed-batch and continuous culture. The shake-flask cultures were suitable as a secondary screening step to deselect strains with bad growth and protein-/ metabolite production patterns. The other batch culture actually decreased the flexibility and complicated the secondary screening step. Small-scale fed-batch culture whereas gave a good prediction of yield obtained in continuous culture. The Long term continuous culture is needed to investigate expression stability.

Benefits with DASGIP

The DASGIP Process Control serves Novo Nordisk with reproducible feeding profiles and ensures well-defined glucose-limited growth conditions. Advanced feeding and stirring capabilities enabled high cell density cultivations, wile avoiding oxygen limitation.

An important factor to Novo Nordisk was the modular concept of the DASGIP Bioreactor System. This concept is ideal for later extensions and tailor-made solutions such as optical DO probes or off-gas analysis system. With little adaption the Danish scientists have also made very good experiences with E. coli fed-batch cultivations in the meantime.

“Ease-of-use, excellent reproducibility and good operational robustness allow application as a highperformance secondary screening tool for strain selection without the need for many replicate experiments. The study has also shown that a scale-up by a factor of 100 was feasible without any surprises”, describes Dr. Peter Becker the DASGIP Bioreactor System. Peter Becker is principal scientist in the microbial fermentation group within the preclinical research at Novo Nordisk A/S. “We appreciate the highquality off-gas analysis data generated by the DASGIP GA4 system very much.”

Media Contact

All latest news from the category: Corporate News

Newest articles

A flexible and efficient DC power converter for sustainable-energy microgrids

A new DC-DC power converter is superior to previous designs and paves the way for more efficient, reliable and sustainable energy storage and conversion solutions. The Kobe University development can…

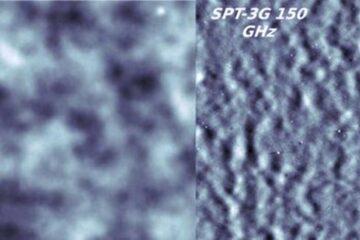

Technical Trials for Easing the (Cosmological) Tension

A new study sorts through models attempting to solve one of the major challenges of contemporary cosmic science, the measurement of its expansion. Thanks to the dizzying growth of cosmic…

Peptides on Interstellar Ice

A research team led by Dr Serge Krasnokutski from the Astrophysics Laboratory at the Max Planck Institute for Astronomy at the University of Jena had already demonstrated that simple peptides…