Virtual reality training for the machine tool industry

Training for machine tool process is often limited by cost and safety concerns, but a new computer-supported learning environment known as VIRTOOL utilises interactive 3D graphics and virtual reality techniques to provide valuable experience to trainees.

Targeting machine tool manufacturers, industrial end-users, and education entities, VIRTOOL makes it possible to simulate the preparation, use and first level maintenance operations of any machine working by means of movement and interaction of solid material.

The environment developed by the IST-funded project is supported by four applications: Master, Generic, Case Generator and Machine. VIRTOOL Master generates machine tool models by building a definition for each machine and assigning this definition to the different assemblies or parts of the whole machine. VIRTOOL Generic allows machine-tools manufacturers and professors to generate specific elements or accessories libraries for different machines, such as cutting tools, holders and fixtures, mounting tools or measurement tools. With the VIRTOOL Case Generator, teachers produce cases or exercises according to the learners’ knowledge and generate the knowledge database that later will provide feedback in VIRTOOL Machine. The teacher can define different types of cases depending the objectives of the learning activities. Based on virtual reality (VR) techniques, the VIRTOOL Machine is the application used in the training process. This application offers the learners a wide range of different interactions by using two and three-dimensional computer interfaces. It imports the machine and elements definition from Master and Generic, and the case information from VIRTOOL Case Generator.

With its virtual reality and 3D-interaction devices, VIRTOOL makes training processes in initial and further vocational education more efficient. It not only reduces the risk for accidents during the training processes when using powerful machine tools, but also reduces the costs for educational processes while increasing the availability of machines that are normally not used by educational centres because of its specialisation. Additionally, VIRTOOL can help machine tool manufacturers explain their complex and complicated products.

“These systems get ready the student before working with the real machinery. They put them in situations that they are going to meet later without fear of probable errors and they have the opportunity of working the necessary time in order to acquire assurance,” says project manager Nieves Alcain from Alecop, Spain. “When these students use the real machinery they will identify the actions that they should execute quickly in order to resolve the specific task. Also, VR systems offer the necessary flexibility in order to practice with machinery that the educational institution does not provide, and therefore they offer the student more knowledge than the theoreticals.”

Since the project ended last year, Nieves says the SMEs owners of the results in the consortium are working in the industrialisation and launching of the four applications resulting from of the project. “These SMEs also are working with other companies to make an agreement for the distribution in their countries,” Alcain explains, adding: “And finally we are analysing the possibilities to apply this new technologies in new technical areas, like automation and automotive.”

Contact:

Nieves Alcain

Alecop Sociedad Cooperativa

Calle Loramendi 11

E-20500 Mondragon

Spain

Tel: +34-943-712405

Fax: +34-943-799212

E-mail: Nalcain@alecop.es

Source: Based on information from VIRTOOL

Media Contact

All latest news from the category: Communications Media

Engineering and research-driven innovations in the field of communications are addressed here, in addition to business developments in the field of media-wide communications.

innovations-report offers informative reports and articles related to interactive media, media management, digital television, E-business, online advertising and information and communications technologies.

Newest articles

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…

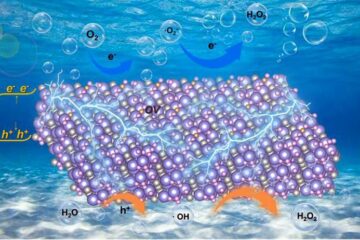

Oxygen vacancies mediated ultrathin Bi4O5Br2 nanosheets

… as efficient piezocatalyst for synthesis of H2O2 from pure water. As an important chemical raw material, hydrogen peroxide (H2O2) is widely applied in various aspects of industry and life….

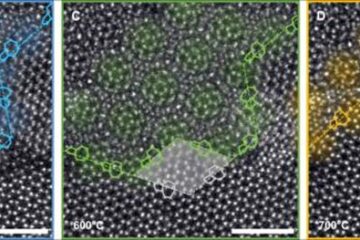

Atom-by-atom: Imaging structural transformations in 2D materials

Silicon-based electronics are approaching their physical limitations and new materials are needed to keep up with current technological demands. Two-dimensional (2D) materials have a rich array of properties, including superconductivity…