ShAPEing the future of magnesium car parts

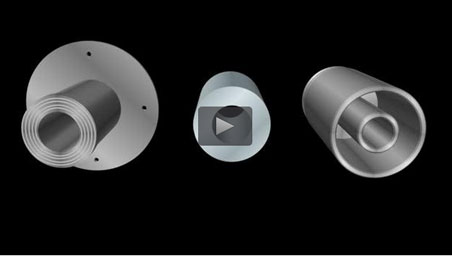

Spinning a magnesium alloy as it is pressed through a die to create tubes rods and channels is more energy efficient and actually improves the alloy's mechanical properties, making them more useful in structural components for vehicles. Credit: PNNL

Magnesium — the lightest of all structural metals — has a lot going for it in the quest to make ever lighter cars and trucks that go farther on a tank of fuel or battery charge.

Magnesium is 75 percent lighter than steel, 33 percent lighter than aluminum and is the fourth most common element on earth behind iron, silicon and oxygen. But despite its light weight and natural abundance, auto makers have been stymied in their attempts to incorporate magnesium alloys into structural car parts. To provide the necessary strength has required the addition of costly, tongue-twisting rare elements such as dysprosium, praseodymium and ytterbium — until now.

A new process developed at the Department of Energy's Pacific Northwest National Laboratory, should make it more feasible for the auto industry to incorporate magnesium alloys into structural components. The method has the potential to reduce cost by eliminating the need for rare-earth elements, while simultaneously improving the material's structural properties. It's a new twist on extrusion, in which the metal is forced through a tool to create a certain shape, kind of like dough pushed through a pasta maker results in different shapes.

Initial research, described recently in Materials Science and Engineering A, and Magnesium Technology, found the PNNL-developed process greatly improves the energy absorption of magnesium by creating novel microstructures which are not possible with traditional extrusion methods. It also improves a property called ductility — which is how far the metal can be stretched before it breaks. These enhancements make magnesium easier to work with and more likely to be used in structural car parts. Currently, magnesium components account for only about 1 percent, or 33 pounds, of a typical car's weight according to a DOE report.

“Today, many vehicle manufacturers do not use magnesium in structural locations because of the two Ps; price and properties,” said principal investigator and mechanical engineer Scott Whalen. “Right now, manufacturers opt for low-cost aluminum in components such as bumper beams and crush tips. Using our process, we have enhanced the mechanical properties of magnesium to the point where it can now be considered instead of aluminum for these applications — without the added cost of rare-earth elements.”

A new spin on things

Researchers theorized that spinning the magnesium alloy during the extrusion process would create just enough heat to soften the material so it could be easily pressed through a die to create tubes, rods and channels. Heat generated from mechanical friction deforming the metal, provides all of the heat necessary for the process, eliminating the need for power hungry resistance heaters used in traditional extrusion presses.

The shape of things to come

The PNNL team designed and commissioned an industrial version of their idea and received a one-of-a-kind, custom built Shear Assisted Processing and Extrusion machine — coining the acronym for ShAPE™.

With it, they've successfully extruded very thin-walled round tubing, up to two inches in diameter, from magnesium-aluminum-zinc alloys AZ91 and ZK60A, improving their mechanical properties in the process. For example, room temperature ductility above 25 percent has been independently measured, which is a large improvement compared to typical extrusions.

“In the ShAPE™ process, we get highly refined microstructures within the metal and, in some cases, are even able to form nanostructured features,” said Whalen. “The higher the rotations per minute, the smaller the grains become which makes the tubing stronger and more ductile or pliable. Additionally, we can control the orientation of the crystalline structures in the metal to improve the energy absorption of magnesium so it's equal to that of aluminum.”

The push to save energy

The billets or chunks of bulk magnesium alloys flow through the die in a very soft state, thanks to the simultaneous linear and rotational forces of the ShAPE™ machine. This means only one tenth of the force is needed to push the material through a die compared to conventional extrusion.

This significant reduction in force would enable substantially smaller production machinery, thus lowering capital expenditures and operations costs for industry adopting this patent pending process. The force is so low, that the amount of electricity used to make a one-foot length of two-inch diameter tubing is about the same as it takes to run a residential kitchen oven for just 60 seconds.

Energy is saved since the heat generated at the billet/die interface is the only process heat required to soften the magnesium. “We don't need giant heaters surrounding the billets of magnesium like industrial extrusion machines, said Whalen. “We are heating — with friction only — right at the place that matters.”

Magna-Cosma, a global auto industry parts supplier, is teaming with PNNL on this DOE funded research project to advance low cost magnesium parts and, as larger tubes are developed, will be testing them at one of their production facilities near Detroit.

PNNL's ShAPE™ technology is available for licensing and could help to make a dent in the auto industry's magnesium target, and slim down cars which currently weigh an average of 3,360 pounds.

###

Reference:

N. Overman, S. Whalen, M. Olszta, K. Kruska, J. Darsell, V. Joshi, X. Jiang, K. Mattlin, E. Stephens, T. Clark, S. Mathaudhu, “Homogenization and Texture Development in Rapidly Solidified AZ91E Consolidated by Shear Assisted Processing and Extrusion (ShAPE),” Materials Science and Engineering A, 701, 56-68, 2017, June 12, 2017, DOI: 10.1016/j.msea.2017.06.062.

S. Whalen, V. Joshi, N. Overman, D. Caldwell, C. Lavender, T. Skszek, “Scaled-Up Fabrication of Thin-Walled Magnesium ZK60 Tubing using Shear Assisted Processing and Extrusion (ShAPE),” Magnesium Technology, 315-321, Feb 16, 2017, DOI: 10.1007/978-3-319-52392-7_45.

Tags: Energy, Fundamental Science, Energy Efficiency, Materials

PNNL LogoInterdisciplinary teams at Pacific Northwest National Laboratory address many of America's most pressing issues in energy, the environment and national security through advances in basic and applied science. Founded in 1965, PNNL employs 4,400 staff and has an annual budget of nearly $1 billion. It is managed and operated by Battelle for the U.S. Department of Energy's Office of Science. As the single largest supporter of basic research in the physical sciences in the United States, the Office of Science is working to address some of the most pressing challenges of our time. For more information on PNNL, visit the PNNL News Center, or follow PNNL on Facebook, Google+, Instagram, LinkedIn and Twitter.

News Center

News Center Home

Secretary of Energy Perry Visit

Latest News

50th Anniversary Features

Director's Column

Social Media Directory

PNNL Leadership

Our Experts

Subscribe to Email News Service

RSS News Feed

Contacts for Reporters

Multimedia

Photos

PNNL B-Roll

PNNL Videos

PNNL's YouTube Channel

Additional Resources

Newsletters

Science Highlights

Publications

EurekAlert! National Lab News

Battelle News

PNNL Speakers Bureau

Media Contact

All latest news from the category: Automotive Engineering

Automotive Engineering highlights issues related to automobile manufacturing – including vehicle parts and accessories – and the environmental impact and safety of automotive products, production facilities and manufacturing processes.

innovations-report offers stimulating reports and articles on a variety of topics ranging from automobile fuel cells, hybrid technologies, energy saving vehicles and carbon particle filters to engine and brake technologies, driving safety and assistance systems.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…