Plasma-zapping process could yield trans fat-free soybean oil product

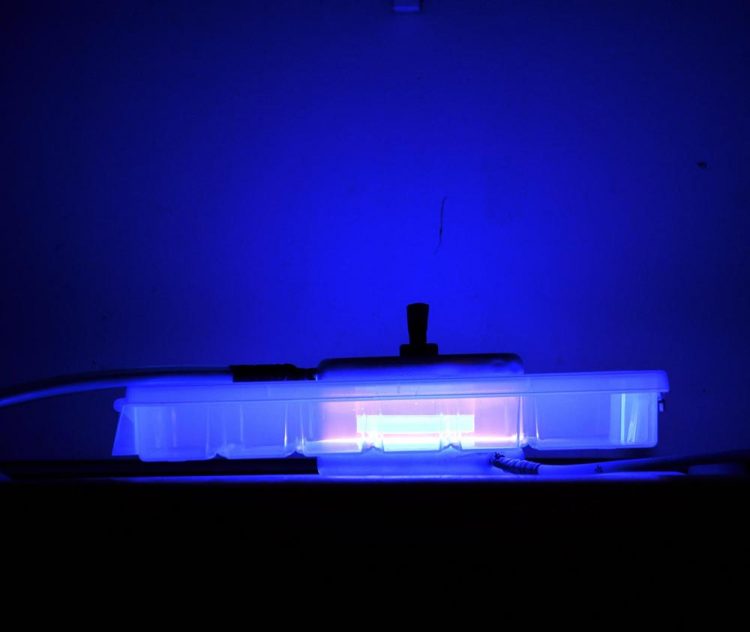

During the high-voltage atmospheric cold plasma treatment, tens of chemical reactions take place each second within the plasma chamber, creating light energy emissions that the researchers can measure to identify what reactions are taking place. Credit: Purdue University / Ximena Yépez

Hydrogenation is a chemical process that transforms liquid vegetable oil to a solid or semisolid state – useful for creating food products like vegetable shortening and margarine. However, the intense heat required in the conventional hydrogenation process causes the formation of harmful trans fats, which can raise cholesterol levels and lead to heart disease and diabetes.

Because of this, the U.S. Food and Drug Administration removed partially hydrogenated oils (PHOs) from the list of safe foods in 2015. Some food manufacturers now use palm oil and other imported oils that do not require hydrogenation, rather than less expensive soybean oil.

To maintain demand for soybeans in the U.S. food market by safely producing PHOs, former Purdue professor Kevin Keener, now at Iowa State University, and doctoral student Ximena Yépez developed a process known as high-voltage atmospheric cold plasma (HVACP) hydrogenation. This process occurs at room temperature, avoiding the high temperatures that cause trans fats to form.

Traditional hydrogenation processes rely on a catalyst, high pressure and high temperatures to separate molecular hydrogen into atoms, Yépez said, but the HVACP process bypasses the catalyst and uses high-voltage electrical discharges to separate the molecules. Once the hydrogen molecule is split, each atom attaches to the double bonds between the molecules in the oil, giving them more structure. More structured molecules cause the oil to become more solid, or “saturated.”

“Cold plasma processes are being researched in many different fields,” Yépez said. “They're used in things like fluorescent lighting, or in changing material properties, like increasing conductivity. Dr. Keener developed this method in food science to eliminate pathogens. But as far as we know, no one has ever used this technology to hydrogenate oil before.”

The HVACP experimental design consists of a small amount of oil placed inside a plasma-filled container, which is then placed inside a bag filled with a hydrogen-blend gas. As the gas fills the bag, two electrodes discharge up to 90 kilowatts of electricity through the chamber, splitting the hydrogen molecules in the gas into ions. These ions bond with the double bonds in the fatty acid molecules on the surface of the oil.

Currently, a typical hydrogenation reaction might produce only a 3 percent increase in saturated fatty acids while increasing the formation of trans fats by up to 40 percent. But after a 12-hour HVACP treatment, the oil showed a 32.3 percent increase in saturated fatty acids and no trans fats. This ratio not only means that the finished product is safer for human consumption, Keener said, but also that the HVACP process is more efficient than traditional processes.

“Because there is no requirement for pressure, catalyst or heat, this process requires up to 50 percent less energy than the current process,” he said. “If you wanted to adapt this for commercial use, you would not be limited by power.”

The researchers said that two main obstacles still exist in adapting the process for commercial use. The first is that the HVACP procedure yields a small amount of byproduct that the researchers have not yet identified. This could be an alternate form of trans fat or a similar substance, said Yépez. The team will manipulate the parameters of the experiment to better understand where the substance comes from and what it might be.

The second obstacle the researchers face is speed. While the process creates more product than heat-based hydrogenation, it is much slower. Yépez and Keener are trying several approaches to make the process faster, including increasing the amount of electricity discharged through the chamber and spraying the oil into the chamber as droplets.

By achieving a realistic speed for the process, Keener's vision is to make the HVACP process an efficient and viable option to create safe PHOs for commercial food production.

“Some of the methods we're investigating could reduce hydrogenation time to a matter of minutes,” Keener said. “Then you could replicate these modules – create a hundred or a thousand of them. And the process isn't just limited to food oils. We can manipulate the chemistry of any oil, plant-based or industrial.

“This process could enable us to produce hydrogenated plant oils in an environmentally friendly way that would be sustainable for the long term.”

Media Contact

All latest news from the category: Agricultural and Forestry Science

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…