X-ray study images structural damage in lithium-ion batteries

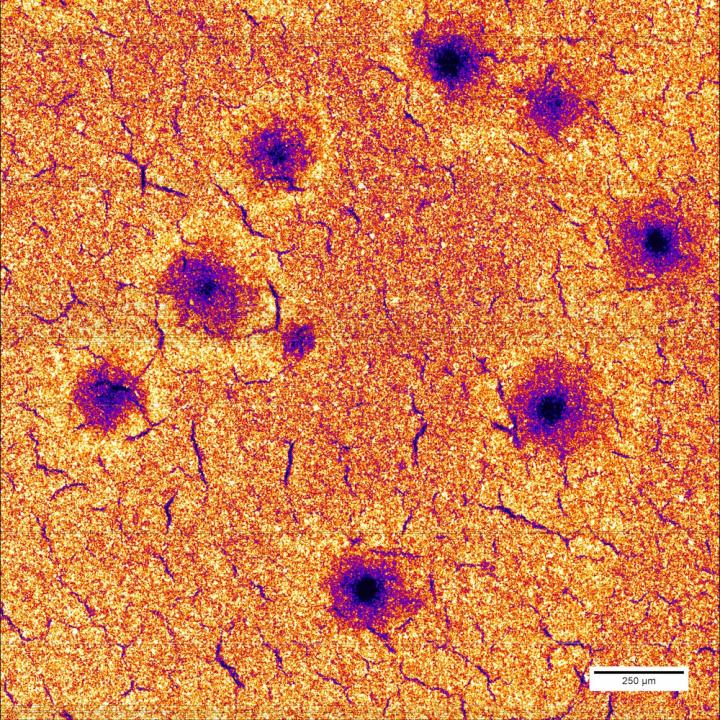

After 25 fast charging cycles, the manganese distribution in the electrode shows large holes. Credit: Ulrike Bösenberg/DESY

Charging lithium-ion batteries too quickly can permanently reduce the battery capacity. Portions of the energy storage structure are thereby destroyed and deactivated.

These structural changes have been visualized for the first time by DESY researcher Dr Ulrike Bösenberg along with her team at DESY's X-ray source PETRA III.

Their fluorescence studies show that even after only a few charging cycles, damage to the inner structure of the battery material is clearly evident, damage which takes longer to arise during slower charging.

The results of the studies will be published in the latest edition of the academic journal Chemistry of Materials (published online in advance).

Lithium-ion batteries are very common because they possess a high charge density. Typically the storage capacity is significantly diminished after one thousand charges and discharges.

A promising candidate for a new generation of such energy storage systems, particularly due to their high voltage of 4.7 Volts, are what are known as lithium-nickel-manganese-oxide spinel materials or LNMO spinels.

The electrodes consist of miniature crystals, also referred to as crystallites, which are connected with binder material and conductive carbon to form the thin layer.

The team around Bösenberg, which also includes researchers from the University of Giessen, from the University of Hamburg and from Australia's national science agency CSIRO, studied the negative electrodes of this LiNi0.5Mn1.5O4 compound at PETRA III's X-ray microfocus beamline P06.

They could determine, with half a micrometre (millionth of a meter) resolution, the precise distribution of nickel and manganese over large areas on the electrode by utilising a novel X-ray fluorescence detector.

The molecular structure of the active material in the battery electrodes is composed of nickel (Ni), manganese (Mn) and oxygen (O) – where the structure is a relatively rigid crystal lattice into which the lithium ions, as mobile charge carriers, can be inserted or extracted.

In their present study, the researchers exposed different battery electrodes to twenty-five charging and discharging cycles each, at three different rates and measured the elementary distribution of the electrode components.

The scientists could show that during fast charging, manganese and nickel atoms are leached from the crystal structure. In their investigation, the researchers spotted defects such as holes in the electrode with up to 100 microns (0.1 millimetre) diameter. The destroyed areas can no longer be utilized for lithium storage.

Utilizing the X-ray fluorescence method in their studies, the researchers took advantage of the fact that X-rays can excite chemical elements into fluorescence, a short-term radiation emission. The wavelength or energy of the fluorescent radiation is a characteristic fingerprint for each chemical element.

This way, the distribution of the individual materials in the electrode can be precisely determined. For this task, the researchers used a novel fluorescence detector, only two of which currently exist worldwide in this form.

This Maia detector, a joint development by CSIRO and Brookhaven National Laboratory in the US, consists of nearly four hundred individual elements that collect the sample's fluorescent radiation. Due to the detector's high energy resolution and sensitivity, it is capable of localizing several chemical elements simultaneously.

The narrow and high-intensity PETRA III X-ray beam could precisely scan the sample surface, which measured approximately 2×2 square millimetres, with a resolution of half a micrometre. Investigating each point took merely a thousandth of a second.

“It is the first time that we could localize these inhomogeneities with such a high spatial resolution over so large an area,” says Bösenberg. “We hope to better understand the effects and to create the foundation for improved energy storage devices.”

What is still puzzling is where the dissolved nickel and manganese atoms end up – this is a question the researchers would like to resolve in further studies. “There are indications that the dissolved material, at least partially, settles on the anode, which inflicts twice the damage to the battery properties,” Bösenberg summarizes.

###

Deutsches Elektronen-Synchrotron DESY is the leading German accelerator centre and one of the leading in the world. DESY is a member of the Helmholtz Association and receives its funding from the German Federal Ministry of Education and Research (BMBF) (90 per cent) and the German federal states of Hamburg and Brandenburg (10 per cent). At its locations in Hamburg and Zeuthen near Berlin, DESY develops, builds and operates large particle accelerators, and uses them to investigate the structure of matter. DESY's combination of photon science and particle physics is unique in Europe.

Reference:

Correlation between Chemical and Morphological Heterogeneities in LiNi0.5Mn1.5O4 Spinel Composite Electrodes for Lithium-Ion Batteries Determined by Micro-X-ray Fluorescence Analysis; Ulrike Bösenberg, Mareike Falk, Christopher G. Ryan, Robin Kirkham, Magnus Menzel, Jürgen Janek, Michael Fröba, Gerald Falkenberg and Ursula E. A. Fittschen; Chemistry of Materials, 27 (7), 2015; DOI: 10.1021/acs.chemmater.5b00119

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…