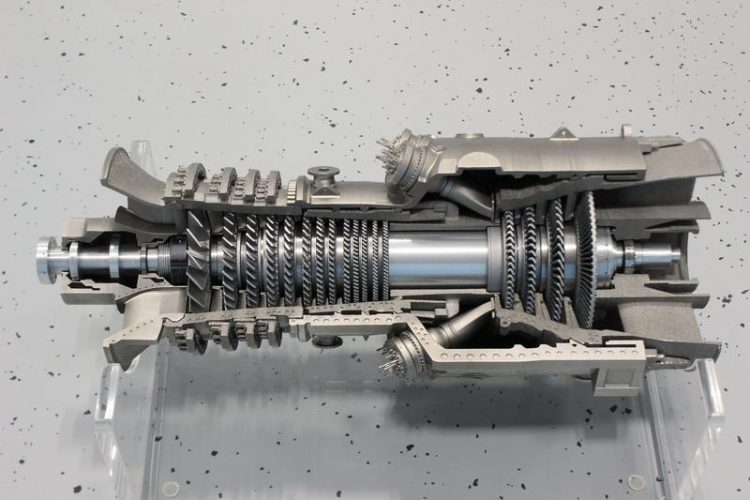

Turbine from the 3D printer

Scaled model of a gas turbine for power generation; completely manufactured with additive manufacturing technologies. Fraunhofer IFAM Dresden

The component assembly consists of 68 parts made of aluminium, steel and titanium, which through component optimisation and the possibilities of Electron and Laser Beam Melting technologies replace the almost 3000 individual parts that make up the original component.

The turbine is fully functional. At the same time the combination of conventional manufacturing technologies – in this case machining – and additive processes with Laser Beam Melting (LBM) and Selective Electron Beam Melting (SEBM) is shown in one component.

Fraunhofer IFAM was involved in the manufacturing of the component as well as the data modification for the technology-adapted production. The housing components with stator stages were manufactured directly on site at the Innovation Center Additive Manufacturing ICAM® in Dresden.

They were produced using Electron Beam Melting (EBM) of Ti-6Al-4V in the Arcam Q20+ plant. The turbine stages and the other housing components were manufactured at H+E using Laser Beam Melting.

The production planning was particularly important and accordingly complex to determine the right technology for each component. The accuracy and roughness of the surfaces, for example, had to be taken into account. Also the necessity and number of support structures as well as the component size had to be considered.

The functionality of the demonstrator was a prerequisite for all considerations. For example, the shaft and turbine stages had to be able to rotate freely between the stator stages and the individual components of the demonstrator had to be connected to each other with minimum effort – by screwing and plugging on.

The components were modified constructively with the experience of the process experts involved in order to be able to manufacture “first time right” for the additive manufacturing technologies used. This goal was achieved. For example, the 316L housing segment could be manufactured by LBM completely without support structures after the adaptations.

The combination of different materials commercially available from the respective plant manufacturers is demonstrated in the component. Not all processed materials correspond to the target materials for turbines. The limitation lies in the fact that these materials cannot yet be processed in such a way that they can be offered commercially.

In the Innovation Center Additive Manufacturing ICAM®, Fraunhofer IFAM Dresden has bundled its technologies in the field of additive manufacturing at one location and can, thus, offer tailor-made solutions for a wide variety of problems from a single source. The customer can choose from Selective Electron Beam Melting, three-dimensional screen printing, Fused Filament Fabrication as well as three-dimensional stencil printing and dispensing at the site.

Marie Jurisch

https://www.ifam.fraunhofer.de/en/Research/additive_manufacturing.html

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…