Spheres can make concrete leaner, greener

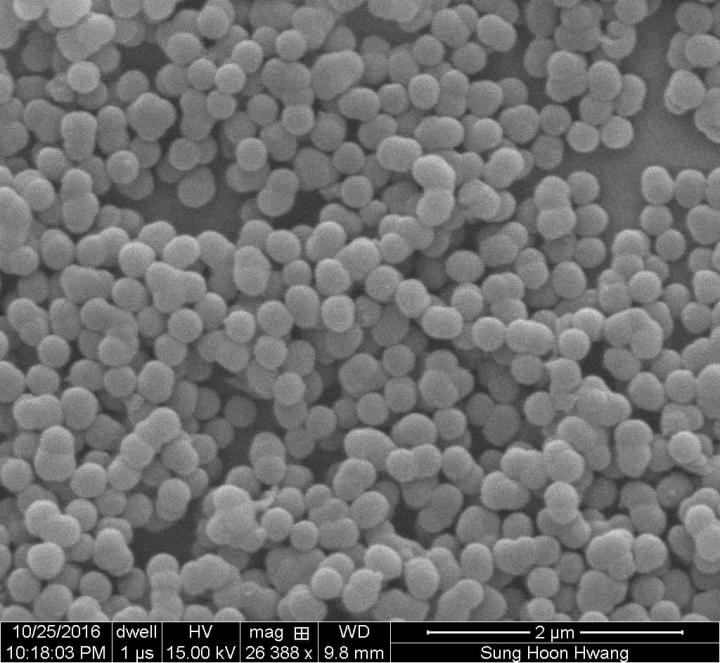

Packed, micron-scale calcium silicate spheres developed at Rice University are a promising material that could lead to stronger and more environmentally friendly concrete. Credit: Multiscale Materials Laboratory/Rice University Usage Restrictions: For news reporting purposes only.

Rice University scientists have developed micron-sized calcium silicate spheres that could lead to stronger and greener concrete, the world's most-used synthetic material.

To Rice materials scientist Rouzbeh Shahsavari and graduate student Sung Hoon Hwang, the spheres represent building blocks that can be made at low cost and promise to mitigate the energy-intensive techniques now used to make cement, the most common binder in concrete.

The researchers formed the spheres in a solution around nanoscale seeds of a common detergent-like surfactant. The spheres can be prompted to self-assemble into solids that are stronger, harder, more elastic and more durable than ubiquitous Portland cement.

“Cement doesn't have the nicest structure,” said Shahsavari, an assistant professor of materials science and nanoengineering. “Cement particles are amorphous and disorganized, which makes it a bit vulnerable to cracks. But with this material, we know what our limits are and we can channel polymers or other materials in between the spheres to control the structure from bottom to top and predict more accurately how it could fracture.”

He said the spheres are suitable for bone-tissue engineering, insulation, ceramic and composite applications as well as cement.

The research appears in the American Chemical Society journal Langmuir.

The work builds on a 2017 project by Shahsavari and Hwang to develop self-healing materials with porous, microscopic calcium silicate spheres. The new material is not porous, as a solid calcium silicate shell surrounds the surfactant seed.

But like the earlier project, it was inspired by how nature coordinates interfaces between dissimilar materials, particularly in nacre (aka mother of pearl), the material of seashells. Nacre's strength is a result of alternating stiff inorganic and soft organic platelets. Because the spheres imitate that structure, they are considered biomimetic.

The researchers discovered they could control the size of the spheres that range from 100 to 500 nanometers in diameter by manipulating surfactants, solutions, concentrations and temperatures during manufacture. That allows them to be tuned for applications, Shahsavari said.

“These are very simple but universal building blocks, two key traits of many biomaterials,” Shahsavari said. “They enable advanced functionalities in synthetic materials. Previously, there were attempts to make platelet or fiber building blocks for composites, but this works uses spheres to create strong, tough and adaptable biomimetic materials.

“Sphere shapes are important because they are far easier to synthesize, self-assemble and scale up from chemistry and large-scale manufacturing standpoints.”

In tests, the researchers used two common surfactants to make spheres and compressed their products into pellets for testing. They learned that DTAB-based pellets compacted best and were tougher, with a higher elastic modulus, than either CTAB pellets or common cement. They also showed high electrical resistance.

Shahsavari said the size and shape of particles in general have a significant effect on the mechanical properties and durability of bulk materials like concrete. “It is very beneficial to have something you can control as opposed to a material that is random by nature,” he said. “Further, one can mix spheres with different diameters to fill the gaps between the self-assembled structures, leading to higher packing densities and thus mechanical and durability properties.”

He said increasing the strength of cement allows manufacturers to use less concrete, decreasing not only weight but also the energy required to make it and the carbon emissions associated with cement's manufacture. Because spheres pack more efficiently than the ragged particles found in common cement, the resulting material will be more resistant to damaging ions from water and other contaminants and should require less maintenance and less-frequent replacement.

###

The National Science Foundation and C-Crete Technologies LLC supported the research.

Read the abstract at https:/

This news release can be found online at http://news.

Follow Rice News and Media Relations via Twitter @RiceUNews.

Related materials:

Multiscale Materials Laboratory (Shahsavari Lab): http://rouzbeh.

George R. Brown School of Engineering: http://engineering.

Rice Department of Civil and Environmental Engineering: http://www.

Rice Department of Materials Science and NanoEngineering: https:/

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation's top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,970 undergraduates and 2,934 graduate students, Rice's undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for lots of race/class interaction and No. 2 for quality of life by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger's Personal Finance. To read “What they're saying about Rice,” go to http://tinyurl.

Media Contact

More Information:

http://dx.doi.org/10.1021/acs.langmuir.8b00917All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…