DuPont fluoropolymers for electrical insulation

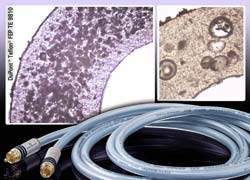

Photo: DuPont <br>New Teflon® FEP TE 9810 (left) produces smaller, better dispersed and more homogenous voids compared to previous Teflon® foam grades (right) for enhanced electrical properties in wires with melt extruded fluoropolymer insulations.

A new foam grade, Teflon® FEP TE 9810, produces smaller, better dispersed and more homogenous voids compared to previous Teflon® foam grades for enhanced electrical properties in wires with melt extruded fluoropolymer insulations. Depending on the construction, this grade, Teflon® FEP TE 9810, has the ability to be self skinning, offering production of cost-effective, high-performance foam insulation for data cables.

It enables the extrusion of all three sections of a skin-foam-skin construction – an inner-skin to ensure mechanical adhesion of the foam to the copper conductor, the foam itself and an outer, protective skin – in a single shot without the need for a second extruder and without the need for a multi-layer crosshead.

Meanwhile a new, licensable extrusion technology from DuPont incorporates air into the extruded Teflon® PTFE insulation for higher performance, low-loss data cables.

DuPont™ Teflon® and DuPont™ Tefzel® fluoropolymers are commonly used for their insulating capabilities under harsh environmental conditions including high temperatures up to 260oC. Whereas Teflon® PTFE, PFA and FEP are chosen for their thermal and chemical resistance in combination with electrical and low-friction properties, Tefzel® ETFE is chosen for its mechanical toughness, ease of processing and high-energy radiation resistance. Both Tefzel® and Teflon® have low dielectric constants and high volume resistivity as well as approved thermal class ratings (SAE, ISO) for wire insulation.

DuPont Fluoropolymer Solutions is a leading producer of fluoropolymer resins, additives, films, finishes and dispersions, PTFE (polytetrafluoro¬ethylene), PFA (perfluoroalkoxy), FEP (fluorinated ethylene propylene), ETFE (ethylene-tetrafluoroethylene) and PVF (polivinylfluoride), marketed under the registered trademarks DuPont™ Teflon®, DuPont™ Tefzel®, DuPont™ Tedlar® and DuPont™ Zonyl®. Major markets for these fluoropolymer products include the automotive, chemical processing, semiconductor, oil exploration, chemical handling, data communication, aerospace, electronics, housewares and building industries.

DuPont is a science-based products and services company. Founded in 1802, DuPont puts science to work by creating sustainable solutions essential to a better, safer, healthier life for people everywhere. Operating in more than 70 countries, DuPont offers a wide range of innovative products and services for markets including agriculture and food; building and construction; communications; and transportation.

The DuPont Oval, DuPont™, The miracles of science™, and Teflon® and Tefzel® are registered trademarks or trademarks of E.I. du Pont de Nemours and Company or its affiliates.

Media Contact

More Information:

http://www.dupont.comAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Machine learning algorithm reveals long-theorized glass phase in crystal

Scientists have found evidence of an elusive, glassy phase of matter that emerges when a crystal’s perfect internal pattern is disrupted. X-ray technology and machine learning converge to shed light…

Mapping plant functional diversity from space

HKU ecologists revolutionize ecosystem monitoring with novel field-satellite integration. An international team of researchers, led by Professor Jin WU from the School of Biological Sciences at The University of Hong…

Inverters with constant full load capability

…enable an increase in the performance of electric drives. Overheating components significantly limit the performance of drivetrains in electric vehicles. Inverters in particular are subject to a high thermal load,…