Power of marine inspiration

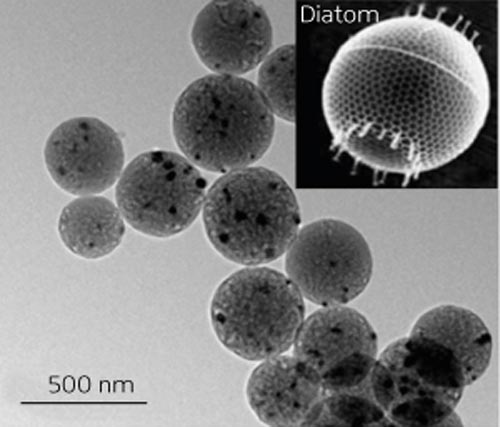

A transmission electron microscopy image of graphitic carbon spheres with a hierarchical pore structure. Inset: A microscopy image of a marine diatom. Adapted with permission from Ref 1. Copyright 2015 American Chemical Society.

Scientists at Singapore's Agency for Science, Technology and Research (A*STAR) have drawn on nature for a breakthrough that significantly enhances the electrochemical performance of lithium-ion batteries. The researchers have developed hierarchical porous carbon spheres to be used as anodes after being inspired by the templated formation of unicellular algae or ‘diatoms’ [1].

“In nature, a great number of microorganisms, like diatoms, can assemble biominerals into intricate hierarchical three-dimensional architectures with great structural control over nano- to millimeter length scales,” explains Xu Li, who heads the research team at the A*STAR Institute of Materials Research and Engineering. “These organisms contain organic macromolecules, which can be used as templates to induce and direct the precise precipitation of silica building blocks to form the complex structures.”

This natural phenomenon inspired Li and colleagues to develop biomimetic strategies based on self-assembled molecular templates to produce hierarchical carbon materials for use as anodic components of batteries.

These materials contain mesopores, which form an interconnected network of channels within the carbon spheres, and have a microporous surface (see image). These three-dimensional features promote ion transport and high storage capacity within the carbon spheres.

Li and the team used organic macromolecules, an aggregate of polymers and cobalt-containing molecules, as templates to make the interconnected mesopores — in a similar way that diatoms create their siliceous structure. The carbon scaffold of the spheres is derived from rings of sugar molecules, which thread on to the pendant polymer chains and form ‘soft’ carbon spheres after hydrothermal treatment.

Pyrolysis causes a cobalt species to catalyze the graphitization process, creating the ‘hard’ carbon spheres. If urea is added before pyrolysis, nitrogen-doped graphitic carbon spheres are made. “The carbon spheres can only be prepared on a laboratory scale, however, we are optimizing the synthetic conditions to scale up fabrication,” says Li.

Next, Li and co-workers tested the carbon spheres as anodes in lithium-ion batteries. The batteries showed high reversible capacity, good cycling stability and outstanding high-rate performance.

Even when the current density is increased 600-fold, 57 per cent of the original capacity is retained. The nitrogen-doped carbon spheres have a higher reversible capacity because of more facile transport of ions and electrons within the doped carbon spheres.

“These results are among the best output to date compared with pure carbon materials,” says Li. “We envisage that batteries composed of these anode materials could be charged faster than those fabricated using conventional carbon materials,” he adds.

The next stage of the research is to extend the application of these materials to other energy storage or conversion systems, and other electrochemical applications, such as electrocatalysis.

The A*STAR-affiliated researchers contributing to this research are from the Institute of Materials Research and Engineering.

Reference

[1] Wang, S.-X., Chen, S., Wei, Q., Zhang, X., Wong, S. Y. et al. Bioinspired synthesis of hierarchical porous graphitic carbon spheres with outstanding high-rate performance in lithium-ion batteries. Chemistry of Materials 27, 336−342 (2015).

Associated links

Original article from A*STAR Research

Media Contact

More Information:

http://www.researchsea.comAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…