Plasma processes paving the way to high performance cutting tools

PVD-coatings for high performance cutting Tools<br>

Metal cutting operations play an especially important role in modern industrial production processes. Based on the tremendous development of multi-axis machine tools, cutting operations represent an ever increasing part of manufacturing process steps.

Instead of preparing specific tools and forms for different work pieces, these are produced in universal machining centers using CAD/CAM control and, in the course of time, a huge amount of cutting inserts.

To realize ever faster production and, at the same time, to guarantee an excellent quality level of the treated workpiece, the development of high performance cutting tools with tailored, wear-resistant coatings has become a key factor for the tool industry.

Multilayered PVD coatings ensure superior wear resistance even under severe cutting conditions. Tailored compositions and architecture of the coatings help to adapt them to tool materials and to the tool geometry used in specific cutting operations, as well as to the work materials to be treated. High power pulse magnetron sputtering (PMS) offers complete flexibility in developing such coatings, be it with respect to the coating material or to the coating architecture. This holds for both high speed and high precision cutting tools.

The pulsed magnetron sputtering process allows deposition of extremely dense and smooth layers free of droplets. By co-sputtering of different materials in a reactive gas atmosphere, a variety of layer compositions, including periodic and aperiodic sequences and graded transitions between individual layers can be synthesized. Single-phase nanocrystalline oxides especially show high thermal stability and chemical inertness. Utilizing advanced pulsed power supplies and a fast feedback control, ternary oxide coatings can also be deposited in long-term, stable deposition processes, resulting in pure single phase coatings. Intrinsic and thermally induced compressive stresses are moderate, and they enhance the wear resistance.

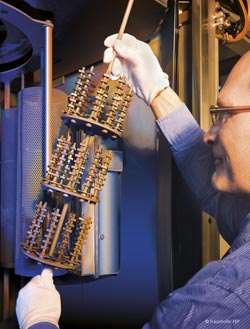

A highly effective plasma pretreatment guarantees excellent adhesion of the coatings. The flange-mounted plasma source LAVOPLAS has been developed to create a dense plasma in a volume corresponding to a typical industrial size batch coating device. It can be used for substrate etching as well as for plasma-activated deposition processes when a high flux of ions is required. The energy of the charged particles can be influenced by a substrate bias voltage to maximize the effect of the preferred ionization or excitation processes. In combination with high power pulsed sputtering, a unique technology sequence for the coating of tools with high-end layer-stacks is available.

Wear-resistant layers are just one example demonstrating the capabilities of plasma and electron beam processes developed at Fraunhofer FEP. You can find more details and a variety of other application examples on our website www.fep.fraunhofer.de, or visit us at the EMO fair in Hannover, at stand no. 54, hall 13, from September 16 – 20, 2013. Together with other Fraunhofer partners we will demonstrate the benefits of advanced plasma techniques for the coating of tools and parts. We are looking forward to welcoming you and discussing your requirements.

Press contact:

Annett Arnold

Fraunhofer-Institut für Elektronenstrahl- und Plasmatechnik FEP | Phone +49 351 2586 452 | Annett.Arnold@fep.fraunhofer.de

Winterbergstraße 28 | 01277 Dresden | Gemany | www.fep.fraunhofer.de

Media Contact

More Information:

http://www.fep.fraunhofer.de/componentsAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…