ORNL research reveals unique capabilities of 3-D printing

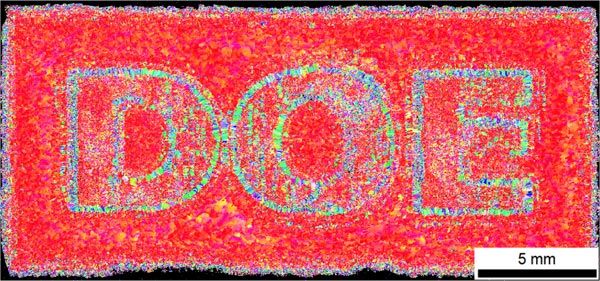

ORNL researchers have demonstrated the ability to precisely control the structure and properties of 3-D printed metal parts during formation. The electron backscatter diffraction image shows variations in crystallographic orientation in a nickel-based component, achieved by controlling the 3-D printing process at the microscale.

Researchers at the Department of Energy’s Oak Ridge National Laboratory have demonstrated an additive manufacturing method to control the structure and properties of metal components with precision unmatched by conventional manufacturing processes.

Ryan Dehoff, staff scientist and metal additive manufacturing lead at the Department of Energy’s Manufacturing Demonstration Facility at ORNL, presented the research this week in an invited presentation at the Materials Science & Technology 2014 conference in Pittsburgh.

“We can now control local material properties, which will change the future of how we engineer metallic components,” Dehoff said. “This new manufacturing method takes us from reactive design to proactive design. It will help us make parts that are stronger, lighter and function better for more energy-efficient transportation and energy production applications such as cars and wind turbines.”

The researchers demonstrated the method using an ARCAM electron beam melting system (EBM), in which successive layers of a metal powder are fused together by an electron beam into a three-dimensional product. By manipulating the process to precisely manage the solidification on a microscopic scale, the researchers demonstrated 3-dimensional control of the microstructure, or crystallographic texture, of a nickel-based part during formation.

Crystallographic texture plays an important role in determining a material’s physical and mechanical properties. Applications from microelectronics to high-temperature jet engine components rely on tailoring of crystallographic texture to achieve desired performance characteristics.

“We’re using well established metallurgical phenomena, but we’ve never been able to control the processes well enough to take advantage of them at this scale and at this level of detail,” said Suresh Babu, the University of Tennessee-ORNL Governor's Chair for Advanced Manufacturing. “As a result of our work, designers can now specify location specific crystal structure orientations in a part.”

Other contributors to the research are ORNL’s Mike Kirka and Hassina Bilheux, University of California Berkeley’s Anton Tremsin, and Texas A&M University’s William Sames.

The research was supported by the Advanced Manufacturing Office in DOE's Office of Energy Efficiency and Renewable Energy.

ORNL is managed by UT-Battelle for the Department of Energy's Office of Science. DOE's Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit http://science.energy.gov.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…