NIST offers electronics industry 2 ways to snoop on self-organizing molecules

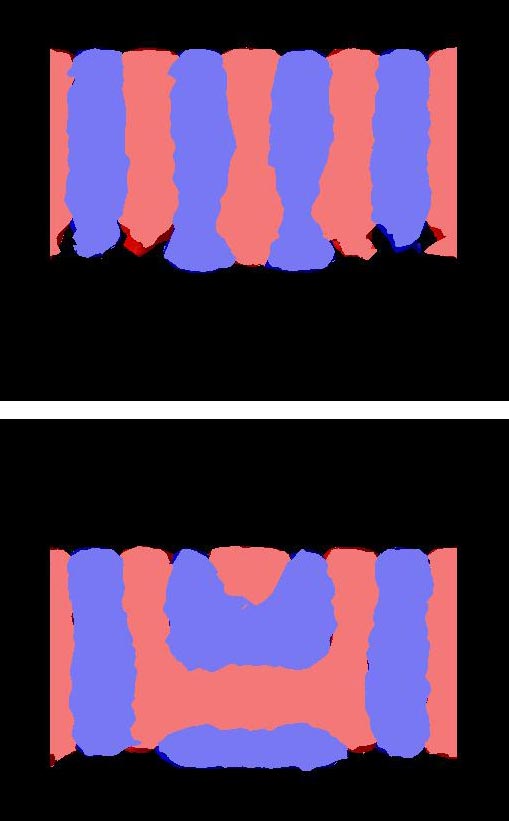

Computer simulations of two possible morphologies of a block copolymer film demonstrate the need for an accurate 3-D imaging tool. Red and blue areas represent the two different phases of the polymer film, seen from the side. Each phase is about 12 nm wide. Viewed from the top, both would appear to have evenly separated rows of the "red" phase, the bottom sample in fact has an unwanted horizontal band that will disrupt the pattern transfer. Soft X-ray scattering data can distinguish the two. Credit: Pitera/IBM Almaden Research Center

Now the day isn't far off when your cell phone may depend on it. Two recent papers emphasize the point by demonstrating complementary approaches to fine-tuning the key step: depositing thin films of a uniquely designed polymer on a template so that it self-assembles into neat, precise, even rows of alternating composition just 10 or so nanometers wide.

The work by researchers at the National Institute of Standards and Technology (NIST), the Massachusetts Institute of Technology, and IBM Almaden Research Center focuses on block copolymers a special class of polymers that under the proper conditions, will segregate on a microscopic scale into regularly spaced “domains” of different chemical composition.

The two groups demonstrated ways to observe and measure the shape and dimensions of the polymer rows in three dimensions. The experimental techniques can prove essential in verifying and tuning the computational models used to guide the fabrication process development.

It's old news that the semiconductor industry is starting to run up against physical limits to the decades-long trend of ever-denser integrated chips with smaller and smaller feature sizes, but it hasn't reached bottom yet. Just recently, Intel Corp. announced that it had in production a new generation of chips with a 14-nanometer minimum feature size. That's a little over five times the width of human DNA.

At those dimensions, the problem is creating the multiple masking layers, sort of tiny stencils, needed to define the microscopic patterns on the production wafer. The optical lithography techniques used to create the masks in a process akin to old-school wet photography are simply not capable of reliably reproducing the extremely small, extremely dense patterns. There are tricks you can use such as creating multiple, overlapping masks, but they are very expensive.

Hence the polymers. “The issue in semiconductor lithography is not really making small features—you can do that—but you can't pack them close together,” explains NIST materials scientist Alexander Liddle. “Block copolymers take advantage of the fact that if I make small features relatively far apart, I can put the block copolymer on those guiding patterns and sort of fill in the small details.” The strategy is called “density multiplication” and the technique, “directed self-assembly.”

Block copolymers (BCPs) are a class of materials made by connecting two or more different polymers that, as they anneal, will form predictable, repeating shapes and patterns. With the proper lithographed template, the BCPs in question will form a thin film in a pattern of narrow, alternating stripes of the two polymer compositions. Alternatively, they can be designed so one polymer forms a pattern of posts embedded in the other. Remove one polymer, and in theory, you have a near-perfect pattern for lines spaced 10 to 20 nanometers apart to become, perhaps, part of a transistor array.

If it works. “The biggest problem for the industry is the patterning has to be perfect. There can't be any defects,” says NIST materials scientist Joseph Kline. “In both of our projects we're trying to measure the full structure of the pattern. Normally, it's only easy to see the top surface, and what the industry is worried about is that they make a pattern, and it looks okay on the top, but down inside the film, it isn't.”

Kline's group, working with IBM, demonstrated a new measurement technique* that uses low-energy or “soft” X rays produced by the Advanced Light Source at Lawrence Berkeley National Labs to probe the structure of the BCP film from multiple angles. Because the film has a regular, repeating structure, the scattering pattern can be interpreted, much as crystallographers do, to reveal the average shapes of the stripes in the film.

If a poor match between the materials causes one set of stripes to broaden out at the base, for example, it will show up in the scattering pattern. Their major innovation was to note that although the basic technique was developed using short-wavelength “hard” X rays that have difficulty distinguishing two closely related polymers, much better results can be obtained using longer wavelength X rays that are more sensitive to differences in the molecular structure.**

While X-ray scattering can measure average properties of the films, Liddle's group, working with MIT, developed a method to look, in detail, at individual sections of a film by doing three-dimensional tomography with a transmission electron microscope (TEM).*** Unlike the scattering technique, the TEM tomography can actually image defects in the polymer structure—but only for a small area. The technique can image an area about 500 nanometers across.

Between them, the two techniques can yield detailed data on the performance of a given BCP patterning system. The data, the researchers say, are most valuable for testing and refining computer models. “Our measurements are both fairly time-consuming, so they're not something industry can use on the fab floor,” says Kline. “But as they're developing the process, they can use our measurements to get the models right, then they can do a lot of simulations and let the computers figure it out.”

“It's just so expensive and time-consuming to test out a new process,” agrees Liddle. “But if my model is well validated and I know the model is going to give me accurate results, then I can crank through the simulations quickly. That's a huge factor in the electronics industry.”

*With the daunting name “resonant critical dimension small angle X-ray scattering” (res-CDSAXS).

**D.F. Sunday, M.R. Hammond, C. Wang, W. Wu, D. Delongchamp, M. Tjio, J. Cheng, J.W. Pitera, R.J. Kline. Determination of the internal morphology of nanostructures patterned by directed self assembly. ACS Nano, 2014, 8 (8), pp 8426–8437 DOI: 10.1021/nn5029289.

***K.W. Gotrik, T. Lam, A.F. Hannon, W. Bai, Y. Ding, J. Winterstein, A. Alexander-Katz, J.A. Liddle, C.A. Ross. 3D TEM Tomography of templated bilayer films of block copolymers. Advanced Functional Materials. Article first published online Oct. 2, 2014 DOI: 10.1002/adfm.201402457.

Media Contact

More Information:

http://www.nist.govAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…