New test opens path for better 2-D catalysts

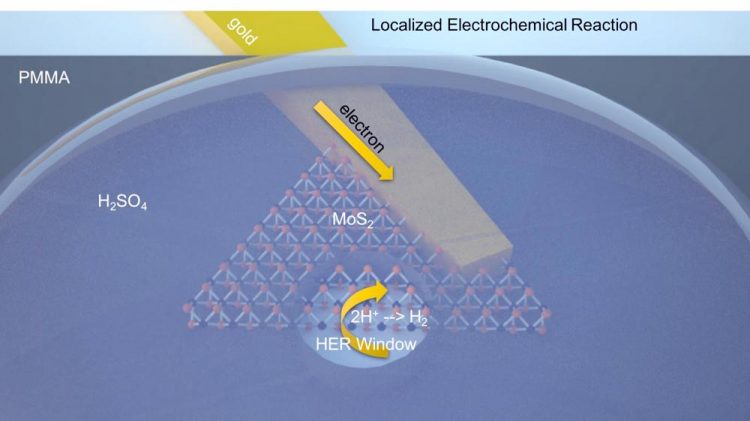

A technique developed by Rice University and Los Alamos National Laboratory will allow researchers to quickly probe atom-thick materials to measure hydrogen production. The Rice lab uses an electron beam to drill submicron holes through an insulating layer of poly(methyl methacrylate) to probe specific areas of nanoscale flakes. Credit: Jing Zhang/Rice University

Rice University researchers have taken a deep look into atom-thick catalysts that produce hydrogen to see precisely where it's coming from. Their findings could accelerate the development of 2-D materials for energy applications, such as fuel cells.

The Rice lab of materials scientist Jun Lou, with colleagues at Los Alamos National Laboratory, developed a technique to probe through tiny “windows” created by an electron beam and measure the catalytic activity of molybdenum disulfide, a two-dimensional material that shows promise for applications that use electrocatalysis to extract hydrogen from water.

Initial tests on two variations of the material proved that most production is coming from the thin sheets' edges. The researchers reported their results this month in Advanced Materials.

Researchers already knew the edges of 2-D materials are where the catalytic action is, so any information that helps maximize it is valuable, Lou said.

“We're using this new technology to identify the active sites that have been long-predicted by theory,” he said. “There was some indirect proof that the edge sites are always more active than the basal planes, but now we have direct proof.”

The probe-bearing microchips developed at Los Alamos and the method created by Lou and lead author Jing Zhang, a Rice postdoctoral researcher, open a pathway to fast screening of potential hydrogen evolution reaction candidates among two-dimensional materials.

“The majority of the material is on the surface, and you want that to be an active catalyst, rather than just the edge,” Lou said. “If the reaction only happens at the edge, you lose the benefit of having all the surface area provided by a 2-D geometry.”

The lab tested molybdenum disulfide flakes with different crystalline structures known as “1T prime” (or distorted octahedral) and 2H (trigonal prismatic). “They're basically the same material with the same chemical composition, but the positions of their atoms are different,” Lou said. “1T prime is metallic and 2H is a semiconductor.”

He said researchers have so far experimentally proved the more conductive 1T prime was catalytic along its entire surface area, but the Rice study proved that to be not entirely accurate. “Our results showed the 1T prime edge is always more active than the basal plane. That was a new discovery,” he said.

After making the flakes via chemical vapor deposition, Zhang used an electron beam evaporation method to deposit electrodes to individual flakes. He then added an insulating layer of poly(methyl methacrylate), a transparent thermoplastic, and burned a pattern of “windows” in the inert material through e-beam lithography. That allowed the researchers to probe both the edges and basal planes of the 2-D material, or just specific edges, at submicron resolution.

The 16 probes on the inch-square chip built at Los Alamos pulse energy into the flakes through the windows. When hydrogen is produced, it escapes as a gas but steals an electron from the material. That creates a current that can be measured through the electrodes. Probes can be addressed individually or all at once, allowing researchers to get data for multiple sites on a single flake or from multiple flakes.

Rapid testing will help researchers alter their microscopic materials more efficiently to maximize the basal planes' catalytic activity. “Now there's incentive to utilize the strength of this material — its surface area — as a catalyst,” Lou said. “This is going to be a very good screening technique to accelerate the development of 2-D materials.”

###

Co-authors are Rice postdoctoral researchers Jingjie Wu and Hua Gao, graduate students Weibing Chen and Jiangtan Yuan, and Pulickel Ajayan, the Benjamin M. and Mary Greenwood Anderson Professor in Engineering and a professor of materials science and nanoengineering, chemistry, and chemical and biomolecular engineering; and Los Alamos researchers Ulises Martinez, Gautam Gupta and Aditya Mohite. Lou is a professor of materials science and nanoengineering.

The Air Force Office of Scientific Research and the Welch Foundation supported the research.

Read the abstract at http://onlinelibrary.

This news release can be found online at http://news.

Follow Rice News and Media Relations via Twitter @RiceUNews

Related materials:

Bubbles help new catalysts self-optimize: http://news.

Lou Group: http://n3lab.

Los Alamos National Laboratory: http://www.

Rice Department of Materials Science and NanoEngineering: https:/

Image for download:

http://news.

A technique developed by Rice University and Los Alamos National Laboratory will allow researchers to quickly probe atom-thick materials to measure hydrogen production. The Rice lab uses an electron beam to drill submicron holes through an insulating layer of poly(methyl methacrylate) to probe specific areas of nanoscale flakes. (Credit: Jing Zhang/Rice University) Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation's top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,879 undergraduates and 2,861 graduate students, Rice's undergraduate student-to-faculty ratio is 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for quality of life and for lots of race/class interaction and No. 2 for happiest students by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger's Personal Finance. To read “What they're saying about Rice,” go to http://tinyurl.

Media Contact

David Ruth

713-348-6327

david@rice.edu

Mike Williams

713-348-6728

mikewilliams@rice.ed

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Silicon Carbide Innovation Alliance to drive industrial-scale semiconductor work

Known for its ability to withstand extreme environments and high voltages, silicon carbide (SiC) is a semiconducting material made up of silicon and carbon atoms arranged into crystals that is…

New SPECT/CT technique shows impressive biomarker identification

…offers increased access for prostate cancer patients. A novel SPECT/CT acquisition method can accurately detect radiopharmaceutical biodistribution in a convenient manner for prostate cancer patients, opening the door for more…

How 3D printers can give robots a soft touch

Soft skin coverings and touch sensors have emerged as a promising feature for robots that are both safer and more intuitive for human interaction, but they are expensive and difficult…