New gel-like coating beefs up the performance of lithium-sulfur batteries

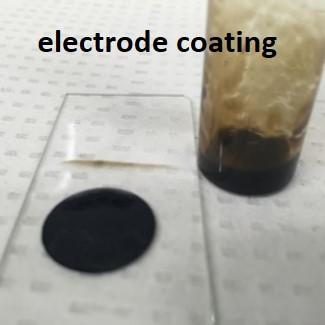

An electrode is coated with a layer of the new material. Credit: Yale University

In a study published online March 20 in the Proceedings of the National Academy of Sciences, researchers describe the new material — a dendrimer-graphene oxide composite film — which can be applied to any sulfur cathode. A cathode is the positive terminal on a battery.

According to the researchers, sulfur cathodes coated with the material can be stably discharged and recharged for more than 1,000 cycles, enhancing the battery's efficiency and number of cycles.

“Our approach is general in that it can be integrated with virtually any kind of sulfur electrode to increase cycling stability,” said Hailiang Wang, assistant professor of chemistry at Yale and lead investigator of the study. “The developed film is so thin and light it will not affect the overall size or weight of the battery, and thus it will function without compromising the energy and power density of the device.”

New types of electrodes — positive and negative terminals — are considered essential for the development of a new generation of high energy-density batteries. As lithium-ion batteries begin to reach their capacity limits, many researchers are looking at lithium-sulfur as a solution. Sulfur is both lightweight and abundant, with a high theoretical energy capacity. However, existing lithium-sulfur battery technology suffers from a loss of capacity during cycling.

The Yale team made its discovery by combining the distinct properties of two material components. They merged the mechanical strength of graphene oxide with the ability of a dendrimer molecule to confine lithium polysulfides. The result is a gel-like slurry that can be readily coated as a 100-nanometer-thin film onto sulfur electrodes.

###

The corresponding authors of the study are Gary Brudvig, the Benjamin Silliman Professor and chair of chemistry, professor of molecular biophysics and biochemistry, and director of the Yale Energy Sciences Institute at Yale West Campus; Yale chemistry professor Victor Batista; and Wang.

Co-authors of the study are Wen Liu, Jianbing Jiang, Ke R. Yang, Yingying Mi, Piranavan Kumaravadivel, Yiren Zhong, Qi Fan, Zhe Weng, Zishan Wu, and Judy Cha, all of Yale, and Henghui Zhou of Peking University.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

“Nanostitches” enable lighter and tougher composite materials

In research that may lead to next-generation airplanes and spacecraft, MIT engineers used carbon nanotubes to prevent cracking in multilayered composites. To save on fuel and reduce aircraft emissions, engineers…

Trash to treasure

Researchers turn metal waste into catalyst for hydrogen. Scientists have found a way to transform metal waste into a highly efficient catalyst to make hydrogen from water, a discovery that…

Real-time detection of infectious disease viruses

… by searching for molecular fingerprinting. A research team consisting of Professor Kyoung-Duck Park and Taeyoung Moon and Huitae Joo, PhD candidates, from the Department of Physics at Pohang University…