Grinding the hardest to reach places within a component

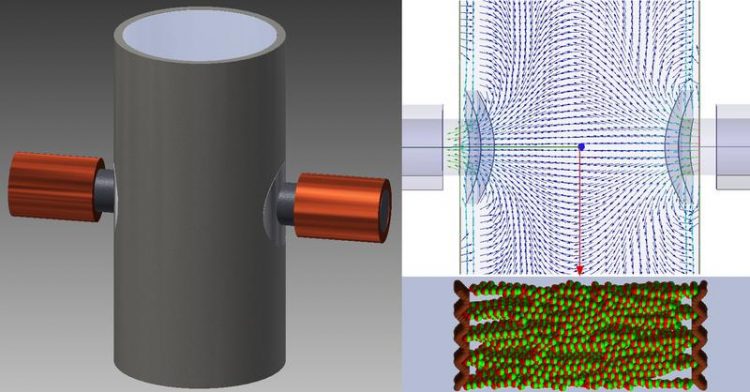

Flow channel with magnetic coils (left). Macroscopic simulation of the magnetic fields within the channel (top right) and a microscopic simulation of the magnetic particles (bottom right). Fraunhofer IWM

This process allows difficult to reach dead volume areas deep inside components to be accurately ground and polished.

Components which have complex shapes often need their inner surfaces to be ground, deburred or rounded so that those surfaces function properly. This is of particular relevance for metallic 3D-printing as well as for medical implants, injection nozzles in automobiles, cooling channels in turbine blades or in any tool in which a recast layer needs to be removed.

Manufacturers enable flow grinding or hydro-erosive rounding by pumping a fluid containing abrasives through the component. These abrasive particles grind along the inner surface of the component, achieving the desired smoothness.

Using magnetorheological abrasive particles to grind in flow dead zones

The results of a conventional flow grinding procedure are largely dependent upon flow dynamics: based on a component’s individual form the abrasive grains in the fluid will have stronger or weaker interaction with different sections, so some parts of the inner surface area will not be properly smoothed. In these dead volumes the flow can almost completely stagnate.

»In such cases, the abrasive grains are completely ineffective, regardless of back and forth pumping«, explains Dr. Claas Bierwisch, scientist in the Powder Technology, Fluid Dynamics group at the Fraunhofer IWM in Freiburg. Using the newly developed process, the abrasive particles are moved by magnets strategically placed on the component. »The magnetorheological abrasive grains are pulled precisely to the area within the component that needs to be addressed – flow force and magnetic strength work together so that the abrasive particles can work within the farthest reaches of the component«, continues Bierwisch.

Simulating magnetorheological flow grinding

It is within this context that the Fraunhofer IWM focuses upon the geometry of a particular component as well as aspects of the flow grinding process which clients require to be customized. The Powder Technology, Fluid Dynamics group is a worldwide leader in predicting the behavior of abrasive grains and their efficacy on component surfaces, through the practical application of mesh-free particle simulations.

»We simulate flow within a system, how long a process will take until completion and recommend the ideal fluid/particle combination and processing methods to component manufacturers so that the desired results can be achieved«, states Bierwisch. »We answer questions such as ‘Where are the dead volumes on a specific component’, ‘How should the magnetic field be designed’ or ‘Will the desired process be achieved by aligning the magnetic abrasive particles or does their movement also need to be steered?’« Answering these types of questions via experiment and trial and error is unthinkable – there are simply too many test variants.

The Fraunhofer IWM simulation team is a core member of a joint project, funded by BMBF (the German Federal Ministry of Education and Research BMBF), with other Fraunhofer Institutes as well as industry partners which ran successful laboratory scale tests on magnetorheological flow grinding in aluminum components. The Fraunhofer Institute for Ceramic Technologies and Systems IKTS tested the magnetic properties within the combination of fluid and particles while the Fraunhofer Institute for Production Systems and Design Technology IPK developed the corresponding systems technology.

As aluminum components are not ferromagnetic, they are well suited to magnetorheological flow grinding. This process is much more complicated when dealing with components composed of magnetizable material, as attaching a magnetic coil to these would produce a strong magnetic field which would need to be factored in to any calculations. Scientists at the Fraunhofer IWM plan to address this in future projects so that magnetorheological flow grinding can also be applied to magnetizable components.

http://www.en.iwm.fraunhofer.de/press-events-publications/details/id/1121/ press release online with further links

http://www.en.iwm.fraunhofer.de/business-units/manufacturing-processes/powder-te… Particle-based Process Modeling

http://www.simpartix.com/ Modeling the mechanics of materials and fluids using mesh-free methods

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…