Graphene-based actuator swarm enables programmable deformation

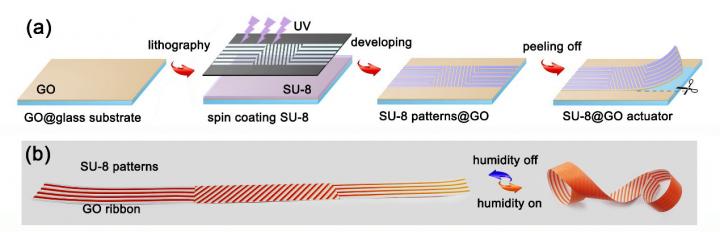

(a) Schematic illustration of the fabrication of patterned SU-8/GO bilayer film using UV lithography. (b) The paper model of patterned SU-8/GO ribbon and its predictable moisture-responsive deformation under humidity actuation. Credit: ©Science China Press

Generally, bilayer structures are widely used for design and fabrication of stimuli responsive actuators. In the past decade, to pursue fast and large-scale deformation, great efforts have been devoted to the development of novel smart materials.

To date, various stimuli response materials/structures have been successfully developed and employed for bimorph actuators.

Recently, graphene and graphene oxide (GO) that possess a series of outstanding physical/chemical properties have emerged as a new type of smart material for actuator design.

Various graphene-based bimorph actuators have been successfully reported. However, these actuators are only capable of simple deformation, such as bending. To the best of our knowledge, less attention has been paid to the refined control of their deformation.

Despite some previous works have reported that the bending direction can be controlled by the patterned constrained layer, their deformation is passively restricted due to the anisotropic mechanical resistance. Currently, the development of bimorph actuators that enable active and programmable deformation remains a challenging task.

In a new paper published in the Beijing-based National Science Review, scientists at Jilin University and Tsinghua University present a self-healing graphene actuator swarm that enables programmable 3D deformation by integrating SU-8 pattern arrays with GO.

Unlike previously published works, the actuator swarm can realize active and programmable deformation under moisture actuation. In this work, the SU-8 pattern arrays can be fabricated into any desired structures, in which an individual SU-8 pattern can be considered as an inert layer.

In combination with the bottom GO layer, each SU-8 structure can form an individual bimorph actuator and deform actively under stimulation. In this regard, these SU-8/GO bilayer arrays can be considered as a swarm of actuators (actuator-1, actuator-2, and actuator-n).

Under external stimulation, each actuator deforms individually, and the deformation of the entire structure is the collective coupling and coordination of the actuator swarm. Therefore, by controlling the size, shape and orientation of the SU-8 patterns, more complex deformations can be programmed. This work proposed a new way to program the deformation of bilayer actuators, expanding the capabilities of existing bimorph actuators for applications in various smart devices.

###

This research received funding from the National Key Research and Development Program of China (2017YFB1104300) and National Natural Science Foundation of China (61590930, 61522503, 61775078 and 61605055).

See the article:

Jia-Nan Ma, Yong-Lai Zhang, Dong-Dong Han, Jiang-Wei Mao, Zhao-Di Chen, and Hong-Bo Sun

Programmable deformation of patterned bimorph actuator swarm

Natl Sci Rev, January 2020; doi.org/10.1093/nsr/nwz219

https:/

The National Science Review is the first comprehensive scholarly journal released in English in China that is aimed at linking the country's rapidly advancing community of scientists with the global frontiers of science and technology. The journal also aims to shine a worldwide spotlight on scientific research advances across China.

Media Contact

More Information:

http://dx.doi.org/10.1093/nsr/nwz219All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…