Engineering living 'scaffolds' for building materials

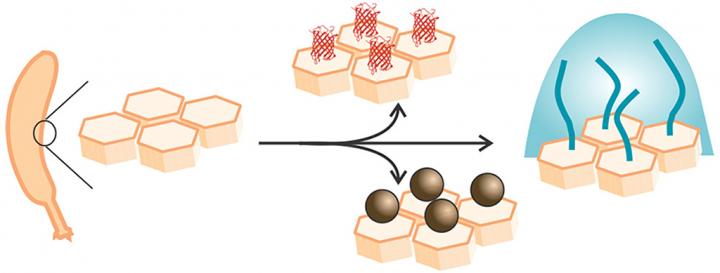

Berkeley Lab researchers built a set of bacteria that can irreversibly attach a variety of hard or soft materials like biopolymers or semiconducting nanoparticles to the cell surface without damaging the cells. Credit: Berkeley Lab

When the inside of a mollusk shell shimmers in sunlight, the iridescence isn't produced by colored pigments but by tiny physical structures self-assembled from living cells and inorganic components. Now, a team of researchers at the Department of Energy's Lawrence Berkeley National Laboratory (Berkeley Lab) has developed a platform to mimic this self-assembly ability by engineering living cells to act as a starting point for building composite materials.

Engineered living materials (ELMs) use living cells as “materials scaffolds” and are a new class of material that might open the door to self-healing materials and other advanced applications in bioelectronics, biosensing, and smart materials. Such materials could mimic emergent properties found in nature – where a complex system has properties that the individual components do not have – such as iridescence or strength.

Borrowing from this complexity seen in nature, the Berkeley Lab researchers engineered a bacterium that can attach a wide range of nanomaterials to its cell surface. They can also precisely control the makeup and how densely packed the components are, creating a stable hybrid living material. The study describing their work was recently published in ACS Synthetic Biology.

“Since hierarchical ordering underlies the properties of many biocomposite materials, being able to regulate the spacing of different components in multiple dimensions is the key to designing predictable ELMs,” said Caroline Ajo-Franklin, a staff scientist from Berkeley Lab's Molecular Foundry who led the study. “Our new platform offers a versatile starting point that opens a wide range of new possibilities for constructing ELMs.”

Both natural structures and the ELMs they inspire are made up of hierarchical patterns of materials. This means that for a material made of regularly sized building blocks, each big block is made of smaller blocks, and each of the smaller blocks is made of even smaller pieces. For example, mollusks build their shells out of superthin “platelets” just 500 nanometers thick, and each platelet is made of millions of tiny nanograins with a diameter of just 30 nanometers.

To control the self-assembly of these types of structures on the surface of living cells, Ajo-Franklin and her team took advantage of surface-layer (S-Layer) proteins to form ordered, sheet-like structures on the surface of many microbes. “It's the difference between building a foundation out of a solid sheet that conforms to the cell surface versus an unordered set of strings,” said Ajo-Franklin, who also holds a joint appointment in Berkeley Lab's Molecular Biophysics and Integrated Bioimaging Division in the Biosciences Area.

The researchers chose the bacterium Caulobacter crescentus since it can survive low-nutrient and low-oxygen conditions, and its S-Layer protein, RsaA, because it is very well-studied. The team engineered RsaA with a biological “lock and key” system to precisely control where and how densely materials attach to the cell surface.

“We built a set of bacteria that can irreversibly attach a variety of hard or soft materials like biopolymers or semiconducting nanoparticles to the cell surface without damaging the cells,” said Marimikel Charrier, scientific engineering associate and lead author of the study. “This living construction kit is a fundamental first step toward creating self-assembling, self-healing, hybrid biomaterials.”

###

This work was supported by the Defense Advanced Research Projects Agency and the National Institutes of Health.

The Molecular Foundry is a DOE Office of Science User Facility.

Founded in 1931 on the belief that the biggest scientific challenges are best addressed by teams, Lawrence Berkeley National Laboratory and its scientists have been recognized with 13 Nobel Prizes. Today, Berkeley Lab researchers develop sustainable energy and environmental solutions, create useful new materials, advance the frontiers of computing, and probe the mysteries of life, matter, and the universe. Scientists from around the world rely on the Lab's facilities for their own discovery science. Berkeley Lab is a multiprogram national laboratory, managed by the University of California for the U.S. Department of Energy's Office of Science.

DOE's Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…