New DuPont™ Crastin® PBT grades cut costs with super-fast moulding cycles

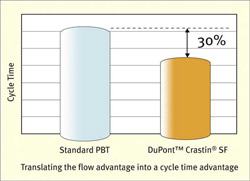

Photo: DuPont <br>In this example comparing glass-reinforced grades, use of DuPont™ Crastin® SF enables a 30 percent drop in cycle time.

“The shorter moulding cycles achieved with Crastin® SF can deliver cost savings ranging up to 20 percent,” said Dave Donofrio, global business manager for Crastin® at DuPont Engineering Polymers. “The super-fast moulding resins are particularly advantageous in moulding thin-wall parts such as connectors and large parts such as structural housings.”

The key to the cycle time reductions provided by the new resins is their exceptionally high flow. For example, the melt viscosity of a 30 percent glass Crastin® SF grade is 43 percent lower than that of a comparable standard grade at 250°C and a typical moulding process shear rate of 1000 s-1.

The high flow of Crastin® SF grades opens the way for major reductions in melt temperature, thus saving precious seconds in the duration of hold pressure and cooling. The chart above shows a typical example.

In addition to reducing cycle time, the enhanced flow of Crastin® SF resins can also enable the design and production of parts with thinner walls. For large parts, this can lead to substantial savings in material consumption and part weight. In the case of small parts, it can permit new part designs with longer, more intricate flow paths. The higher flow of Crastin® SF resins also opens the way to cost savings through the use of moulds with more cavities. Alternatively, because Crastin® SF requires lower injection pressure, the moulder can employ a smaller machine, which costs less to buy and to operate.

The mechanical properties of the new resins are very similar to those of comparable standard grades, according to Donofrio. “We achieve that impressive result with new technology that enhances the flow of polymer chains at the molecular level while maintaining the properties expected for comparable PBT resins,” he said.

For more information about DuPont™ Crastin® SF super-fast moulding resins, please visit plastics.dupont.com.

The DuPont Engineering Polymers business manufactures and sells Crastin® PBT and Rynite® PET thermoplastic polyester resins, Delrin® acetal resins, Hytrel® thermoplastic polyester elastomers, DuPont™ ETPV engineering thermoplastic vulcanizates, Minlon® mineral-reinforced nylon resins, Thermx® PCT polycyclohexylene dimethylterephthalates, Tynex® nylon filaments, Vespel® parts and shapes, Zenite® liquid crystal polymers and Zytel® nylon resins and Zytel® HTN high-performance polyamides. These products serve global markets in the aerospace, appliance, automotive, consumer, electrical, electronic, healthcare, industrial, sporting goods and many other diversified industries.

DuPont is a science-based products and services company. Founded in 1802, DuPont puts science to work by creating sustainable solutions essential to a better, safer, healthier life for people everywhere. Operating in more than 70 countries, DuPont offers a wide range of innovative products and services for markets including agriculture and food; building and construction; communications; and transportation.

The DuPont Oval, DuPont™, The miracles of science™, and Crastin® are registered trademarks or trademarks of E.I. du Pont de Nemours and Company or its affiliates.

Media Contact

More Information:

http://www.dupont.comAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…