'Bottlebrush' polymers make dielectric elastomers increasingly viable for use in devices

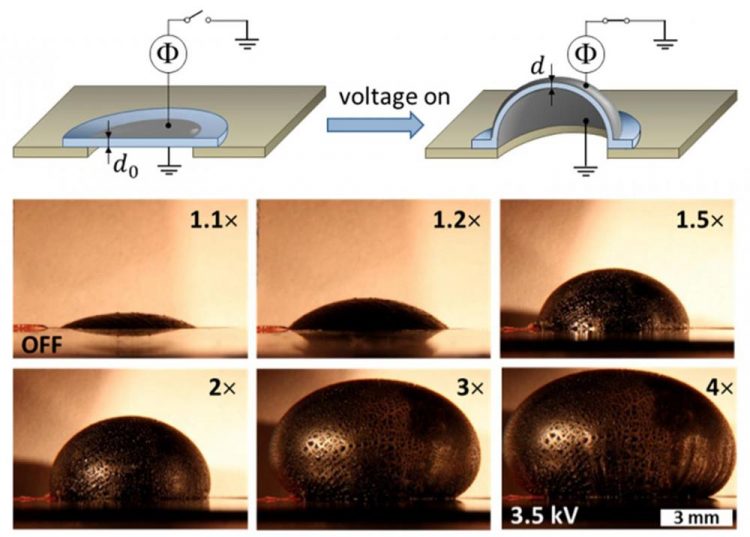

This image shows electrical response of a circular diaphragm composed of a pure bottlebrush elastomer upon electroactuation with increasing voltage and without any external pre-strain. The numbers indicate the electric field-induced area expansion under constant-volume conditions at room temperature. Credit: Richard Spontak

“Dielectric elastomers are the most responsive electroactive polymers in terms of achievable strains, but two big hurdles have effectively prevented the smart materials community from using them in commercial devices,” says Richard J. Spontak, Distinguished Professor of Chemical and Biomolecular Engineering and professor of materials science and engineering at NC State, who co-authored a paper describing the new materials.

“First, previous dielectric elastomers required large electric fields in order to trigger actuation, or movement — on the order of at least 100 kilovolts per millimeter (kV/mm). With our new material, we can see actuation at levels as low as ca. 10 kV/mm.”

“The second challenge is that, previously, materials had to be pre-strained,” Spontak says. “This would either mean using a frame to physically strain the material, or adding a second component to the polymer to retain the strain after it was applied. But our material consists of a single component that is specifically designed at the molecular level to inherently possess pre-strain. In other words, we don't need a frame or a second component – our material is ready to be used as soon as it is cross-linked into a specific shape.”

The new material that has permitted this breakthrough is a “bottlebrush” silicone elastomer, which has been engineered to possess these unique properties, and it is not difficult to manufacture.

“We are working specifically with bottlebrush polymers, which are prepared by grafting long polymeric side chains to a polymer backbone,” says Sergei S. Sheiko, George A. Bush, Jr. Distinguished Professor of Chemistry at UNC and corresponding author of the paper.

“The resulting molecules may be viewed as filaments that are thick, yet remain quite flexible, which allows for significant reduction of the materials' rigidity and makes them more stretchable. Furthermore, the mechanical properties can be controlled by varying the bottlebrush architecture – for example, by preparing molecules with different degrees of polymerization of grafted chains and different grafting densities.

“This architectural control of mechanical properties has reduced the limit of stiffness in dry polymer materials by 1,000 times, demonstrated extensibility of up to eight times, and opened up new applications not available to stiffer materials or materials with liquid fractions,” Sheiko says. “One of these applications — their use as free-standing dielectric elastomers – has been demonstrated, which we discuss in this paper.”

“We're at the earliest stages of identifying all the potential ways in which we could use this new class of material,” Spontak says. “It works better than anticipated, and now we're beginning to consider potential applications.”

###

The paper, “Bottlebrush Elastomers: A New Platform for Freestanding Electroactuation,” is published in the journal Advanced Materials. Lead author of the paper is Mohammad Vatankhah-Varnoosfaderani, a postdoctoral researcher at UNC. The paper was co-authored by William F. M. Daniel, Alexandr P. Zhushma, Qiaoxi Li and Benjamin J. Morgan of UNC; Daniel P. Armstrong of NC State; Krzysztof Matyjaszewski of Carnegie Mellon; and Andrey V. Dobrynin of the University of Akron. The work was done with support from the National Science Foundation under grants DMR 1122483, DMR 1407645, DMR 1436201 and DMR 1409710, and from Becton Dickinson Technologies.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…